To meet tough emissions legislation for Europe and North America, JCB is offering a brace of new machines powered by its latest diesel, the new Ecomax engine. JCB’s backhoe loaders, telehandlers and smaller JS excavators will be the first machines fitted with the new Ecomax engine. However this will also be installed into various models in the line-up including those in the wheeled loader, skid steer loader and rough terrain forklift ranges.

September 4, 2012

Read time: 4 mins

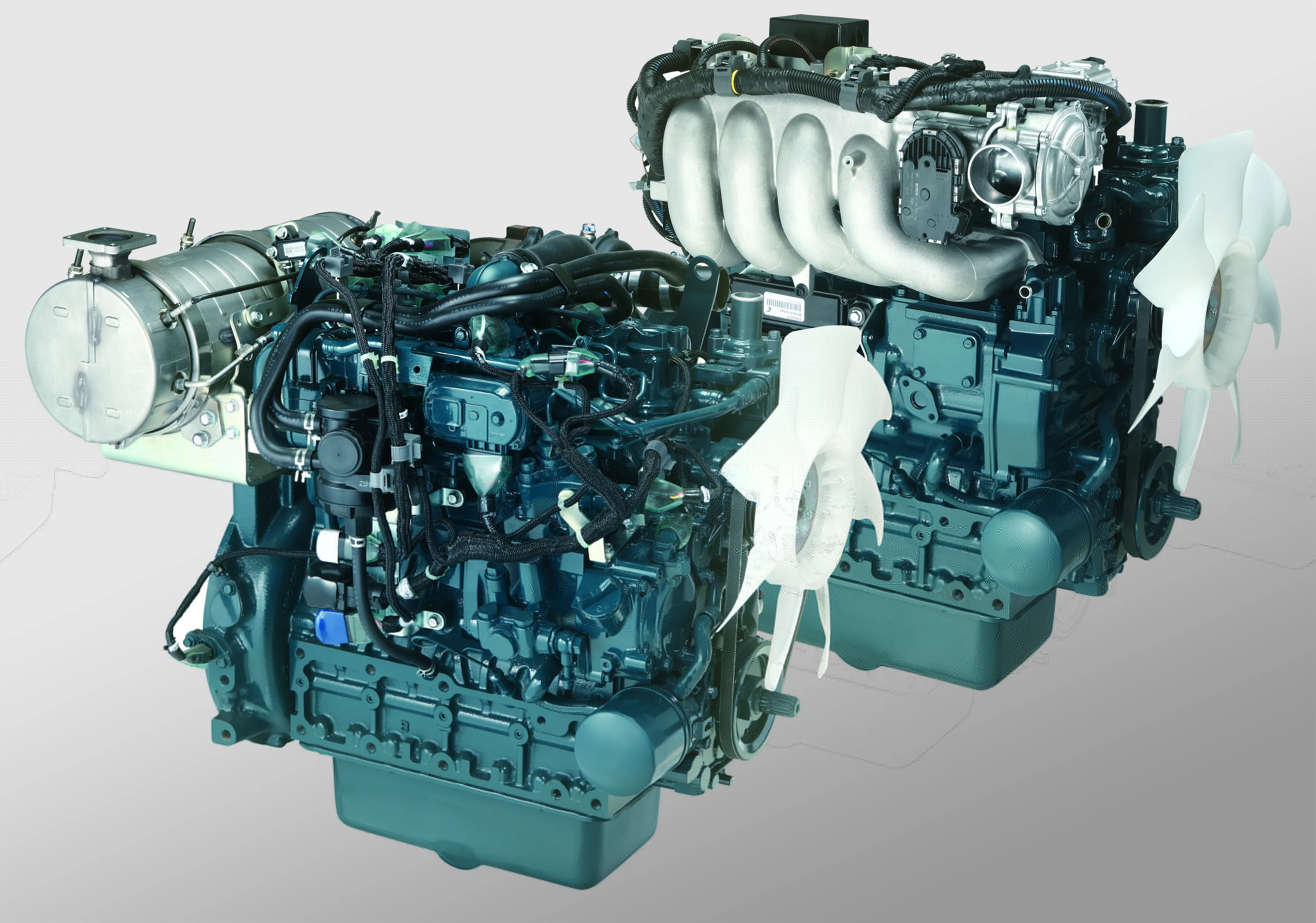

To meet tough emissions legislation for Europe and North America, JCB is offering a brace of new machines powered by its latest diesel, the new Ecomax engine.

Ollie Howlett is engine service manager at JCB and explained that the Tier 4 Interim/Stage IIIB engine features patented combustion bowl geometry. Howlett said, “It’s cleaner and more efficient and means virtually no soot leaves the combustion chamber.”

Other key components for the Ecomax engine’s low emissions are the Delphi high pressure, common rail fuel system that operates at 2,000bar as well as the Borg Warner variable geometry turbocharger and exhaust gas recirculation (EGR) package. He said, “Computational flow dynamics was used to design the manifold. Fuel consumption of this engine is very low.” And he said it offers fuel savings of some 5-10% over the previous Stage IIIA/Tier 3 engine. Other key benefits of the Ecomax include an ability to run on standard engine oils with no additional service requirements.

There have been questions in the market over the secondhand value of Stage IIIB/Tier 4 Interim machines as many have previously been sold overseas to countries where the necessary low sulphur fuel is not available. But a major advance with the Ecomax engine is that it can be recalibrated by a JCB dealer for use in nonlegislated markets. Howlett said, “It maximises the residual value to our customers.”

The engine now offers a broader spread of power outputs, with an increase at the top end to a maximum of 129kW and a low output rating of 55kW.

The 3CX backhoe loader is now available in different versions with the more basic models aimed at rental fleets and the high specification units intended for owner-operators. There are numerous specification options, with power outputs of 55, 68 or 81kW and choices of conventional or excavator style controls. The new engine offers better fuel consumption figures than the earlier generation diesel despite power increases, while sophisticated hydraulics also contribute to an improvement in overall efficiency. An improved powerslide is available for the backhoe with a new steel wire rope said to be more durable than the chain it replaces, while a CE-approved quick-hitch system featuring sensors and audible warnings for safety is also offered. Pads can be fitted underneath the bucket to protect a road surface (and eliminate the need to pay for reinstatement costs) for when the machine is being used for utility work. Mohan added, “We have the option of a front shovel ram guard.”

The lower power 55kW model is an important development as it will meet the needs of rental customers and this machine is also Tier 4 Final compliant. The electronic engine allows remote motoring through the JCB Livelink system. For plant hire firms this is a key issue, as it allows remote monitoring of performance. Faults can be addressed before they develop into more serious problems. Earlier this year JCB introduced the JS240, JS260, JS330 and JS360 crawler excavators with Stage IIIB/Tier 4 Interim compliant Isuzu diesels and the firm is now offering the smaller JS115, JS130 and JS145 excavators with its own Ecomax engines to meet the necessary legislation. The new engines are at the centre of model improvements, permitting reduced operating costs, ease of operation and improved fleet management. As there is no DPF, maintenance costs will be lower than for some competing machines and Mohan added, “Visibility is maintained because there is no DPF.”

The JS145LC excavator instance is powered by a 68kW version of the new Ecomax engine, offering a 10% reduction in fuel consumption and featuring a new cooling system designed to lower working noise. Safety is improved due to

the good all-round visibility as well as the rear view camera with display on the main screen. Security is improved due to a PIN code system that prevents unauthorised use.