A new asphalt plant has offered a major productivity and efficiency gain for a producer in the US. The privately-owned Tully Group has opted to replace two batch plants with a single large plant for its operation in the US state of Connecticut.

The Tully Group’s Tully Construction Company has been a major asphalt producer/contractor in New York for many years and has had success in producing and placing RAP in the area. When the Tully Group purchased the Galasso Materials operation in East Granby, three batch plants were located at the quarry site and the firm decided to expand its operations in Connecticut.

The company opted to install a new 453tonne/hour High RAP Double Barrel XHR HMA plant at the East Granby quarry, shutting down two existing batch plants. Current permit guidelines require plants be located away from water sources, schools, and other sensitive areas. At the East Granby location, the Tully Group made a joint agreement with Connecticut's Department of Energy and Environmental Protection (CT DEEP) to surrender the operating permits for the two oldest plants on the site as part of CT DEEP’s approval to allow Tully to install the cleaner and more efficient

For its plant in Queens, Tully has typically used up to 60% RAP on private commercial projects that require a minimum of 50% RAP, according to Tully. For one city parking lot project that was designated a green drainage area, the company produced around 9,000tonnes of asphalt containing up to 60% RAP to meet the requirements.

Currently, 80-90% of Tully’s asphalt work is for road agencies, with the remaining focused on commercial work. In New York the company is required to use 30% RAP on city streets, while in Connecticut it can use 15% RAP and up to 20% with specific engineer approval in all surface courses for all road agency work. But Tully says that as agencies realise the cost benefit of using more RAP, along with the environmental aspects of recycling more material, it expects to see higher percentages of RAP being used.

The new plant was run at approximately 80% of capacity this past season and supplied most of the material for the firm’s four paving crews in the area. With six 272tonne storage silos, the firm plans for the plant to produce 90% of the asphalt from its East Granby site. Tully added that 80% of all production from the facility is for its own paving crews, with the remaining 20% sold to independent contractors. And with three recycling bins, the firm is set up to incorporate as much RAP as agencies and its other customers will allow.

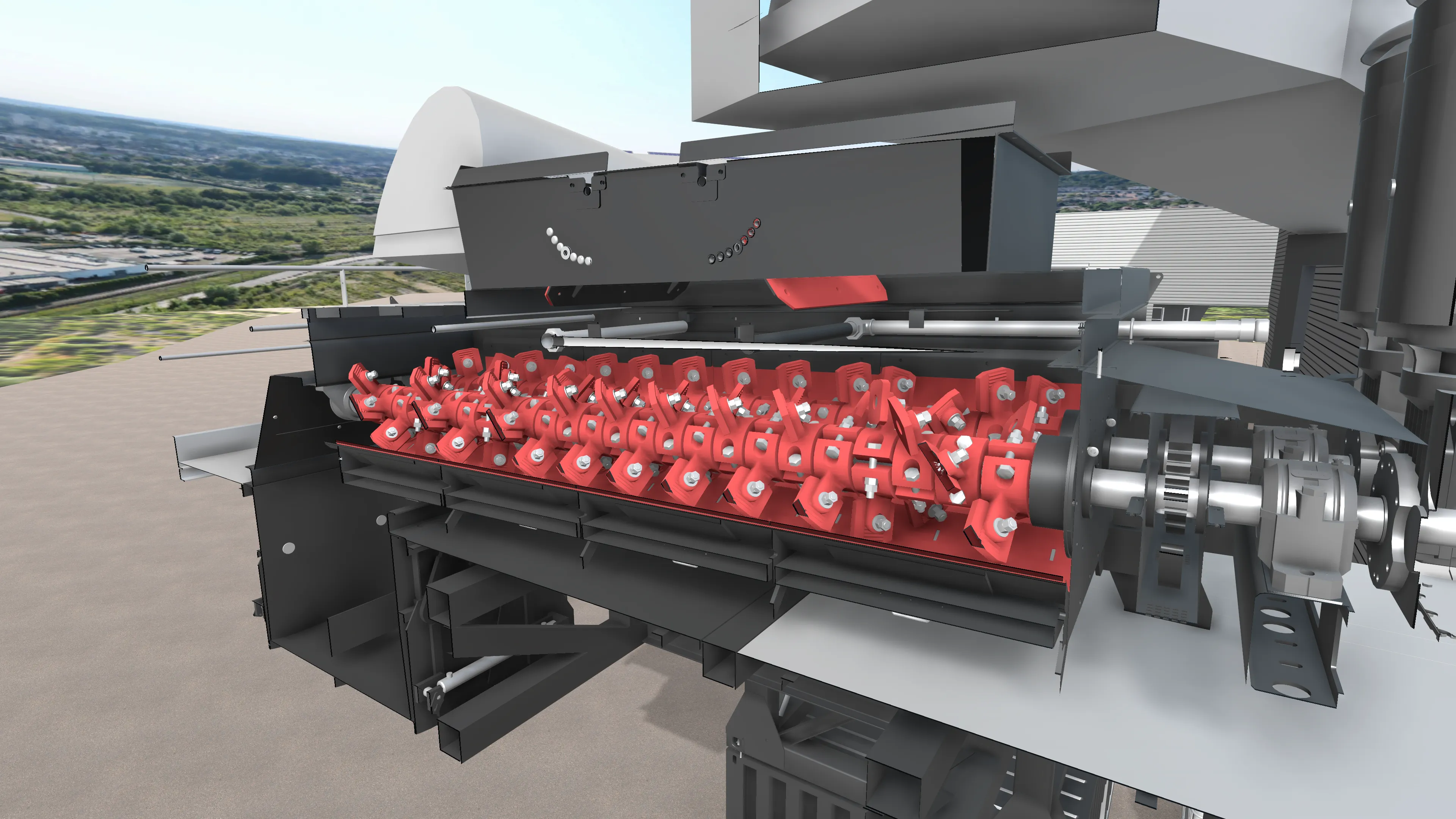

Other major components supporting the mixer drum, fired by a Phoenix Talon combination gas/oil burner, include a seven-compartment cold feed system, a dual deck scalping screen and twin shaft asphalt mixer. They also include a Pulse Jet Baghouse, a low-profile truck scale, a pilot control centre equipped with the Total Control II-HMA PLC Control System, a Heatec 2 gas/oil heater, and three vertical insulated asphalt tanks.