While reclaimed asphalt pavement is not a new idea, there are new and innovative technologies coming all the time to improve its application and durability.

This RAP is “black gold”, as Thierry De Sars, technical director at Groupe

But it all comes down to cost savings and efficiencies that importantly include increasingly precise dozing to get the exact amount of bitumen laid down on a pass.

De Sars cautioned delegates that imported bitumen from RAP may have deteriorated to a sufficient degree that the road project is compromised. For one thing, the imported bitumen may have reduced mixability at the plant.

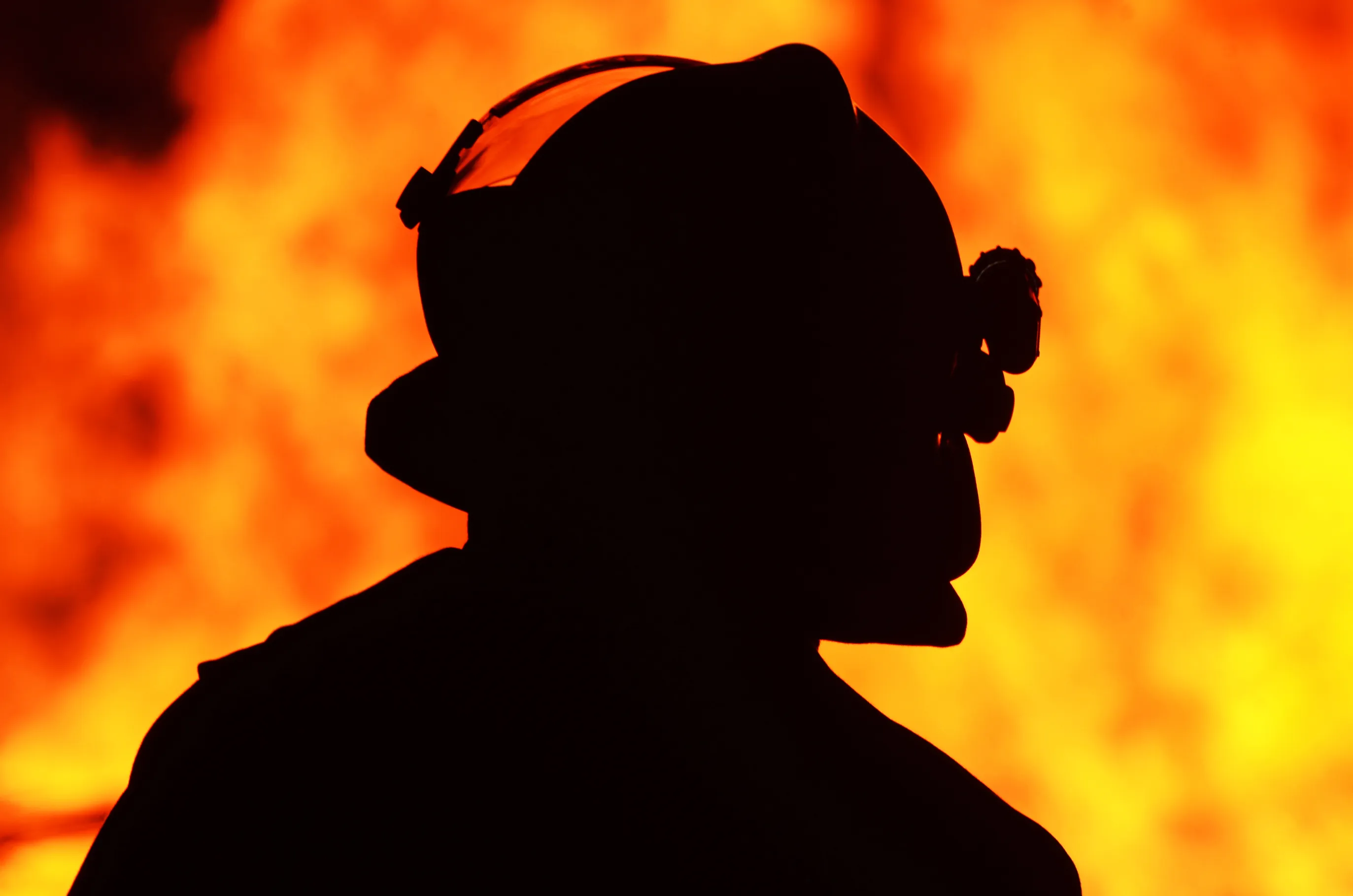

The Retroflux technology from Fayat, the French civil engineering, general and steel construction and energy services provider, has along thermal heating exchanger to protect the bitumen from overheating. Also, from a health and safety standpoint, the Bitumen vapours are consumed in flames.

Yet innovation is not just about technology, said Andreas Marquardt, head of exports at

Never underestimate the need to sell your technology and projects to potential customers. However, as a machine supplier, you must always listen to the client about how the machinery is operating. No matter how tried and tested the equipment, there is always something learn about its performance. Building this data bank from global projects is essential for knowing where to start improving equipment.

But for innovation to come about, all partners need to listen and learn, he explained. Importantly, never forget that brand reputation almost always comes from not from the machinery being used on a project but how the companies work together to make progress and solve problems.