With substantial corporate changes for two of the major manufacturers of milling machines, the market is in a state of some flux. Only a few months ago Atlas Copco bought its fellow Swedish firm Dynapac, followed shortly afterwards by the announcement that another Swedish company, Volvo, was planning to acquire Ingersoll Rand's road development range.

Exactly how these two large businesses will be integrated into Atlas Copco and Volvo remains to be seen. Both Atlas Copco and Volvo will face a learning c

April 16, 2012

Read time: 4 mins

New millers make their debut against a background of strong demand

With substantial corporate changes for two of the major manufacturers of milling machines, the market is in a state of some flux. Only a few months agoExactly how these two large businesses will be integrated into Atlas Copco and Volvo remains to be seen. Both Atlas Copco and Volvo will face a learning curve when it comes to developing road machinery sales and support networks. However, the move reflects recognition of the importance of the road machinery market. With milling forming a cornerstone of the road machinery sector, it seems the market for these machines will become increasingly competitive as the new owners develop their presence.

At the recent World of Asphalt event in Atlanta, a number of the firms in the sector also exhibited new machines and technologies in public for the first time and explained the importance of their latest developments.

Growing line

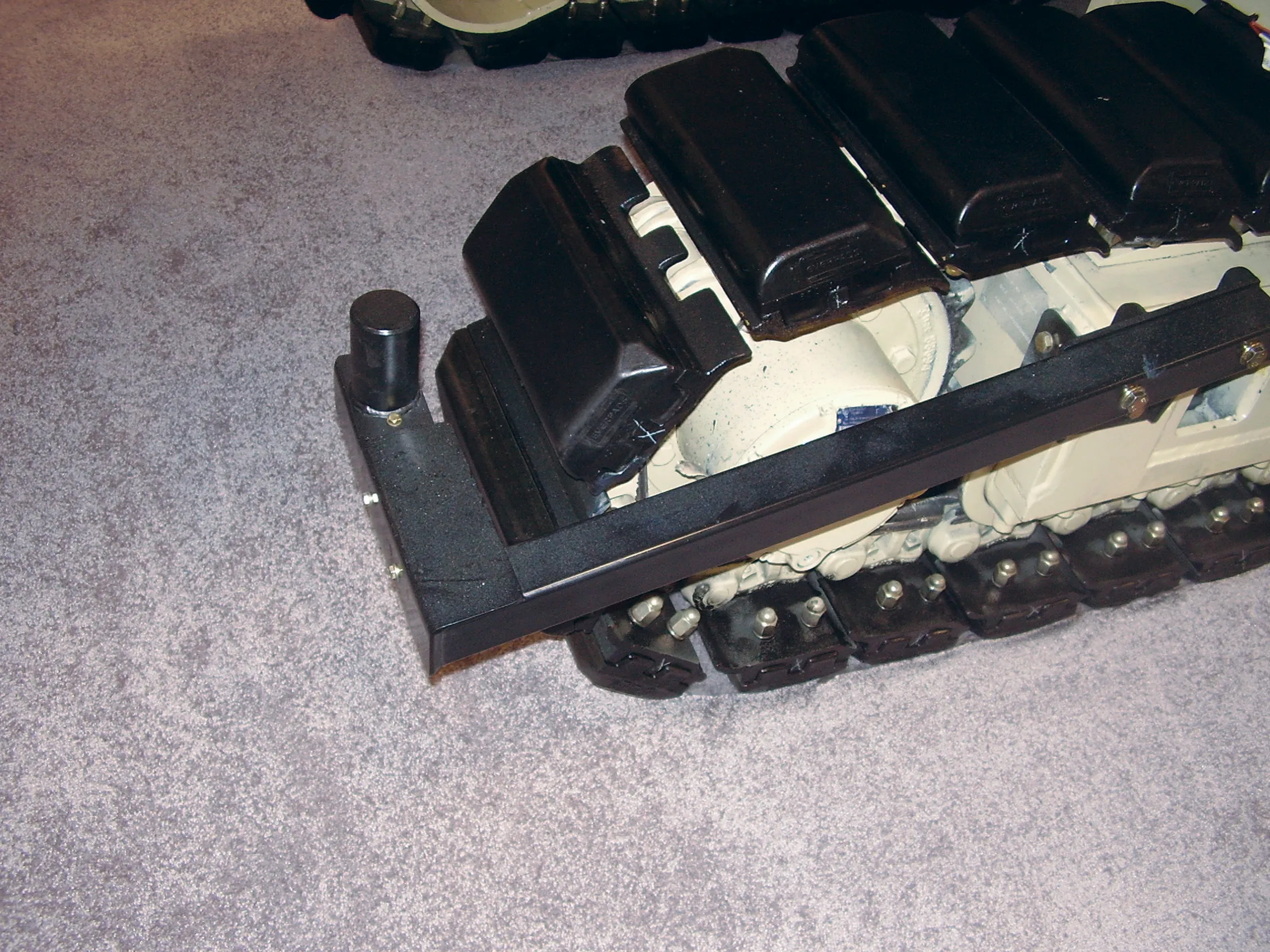

The Ingersoll Rand milling line saw its first model introduction in the middle of last year, with the launch of the 500mm class machine. In recent months this has been followed by the larger 2m class machine, the new MT-2000 and both are atPower comes from a

Emphasis has been put on ease of use and Wakefield said, "It's relatively easy to find the controls. It's laid out as if you're looking down at the machine."

The control panel can also be folded away at night to reduce the risk of damage by vandals, while Wakefield added night working has been catered for too, "It's backlit."

Wakefield said that the designers are aware of the dangers involved in operating a machine on a busy site and said, "We really try to improve safety in the machines."

A rear view CCTV camera is fitted to prevent reversing accidents while an active obstacle detection system is installed that uses a sonic sensor to check for any obstacles. "It'll stop the propel drive in an instant," Wakefield said, adding, "There is a 30 second manual override too."

A conveyor that folds hydraulically is offered as an option and this useful for ease of transport or use in confined spaces. The barrel for the drum is made in the Shippensburg facility and

The machine offers a number of different grade and slope controls and can work with sonic controls or a conventional wire rope system. Wakefield added, "It will be able to use the

The first two 500mm machines are now operating in Europe, while the machine at World of Asphalt is the first in the US. Wakefield added, "We have some 2m machines out testing with customers." Although the MT-2000 makes a 2m wide cut as standard, it can be used for larger milling widths and Wakefield said, "You can put on a 2.185m drum."

However the company is keen to develop its milling range further and for the future, the firm is looking at the 2100 and 2200 classes as these will better suit full line milling applications. Wakefield said, "We're still working on concepts."