The Kivikko industrial area in Finland, which is owned by the City of Helsinki, has expanded gradually over the years and it has expanded again with the new stabilised area now about 3.5hectares. The ALLU equipment and system was used to stabilise Kivikko for the first time in 2001, and the latest job started in June 2010 with the stabilisation work completed by mid-December 2010. [The ALLU Stabilisation System is a Finnish invention that provides a fast, cost-effective and environmental-friendly working

February 15, 2012

Read time: 3 mins

Contractor 2655 Biomaa used ALLU for stabilising the foundation layers for an industrial area in the Finnish capital Helsinki

The Kivikko industrial area in Finland, which is owned by the City of Helsinki, has expanded gradually over the years and it has expanded again with the new stabilised area now about 3.5hectares.

The2180 ALLU equipment and system was used to stabilise Kivikko for the first time in 2001, and the latest job started in June 2010 with the stabilisation work completed by mid-December 2010. [The ALLU Stabilisation System is a Finnish invention that provides a fast, cost-effective and environmental-friendly working method for hardening and dynamic strengthening of soft soils as well as for improving the soil's deformation properties].

Lead contractor for the Helsinki job, Biomaa from Nurmijärvi, Finland, has many years of stabilisation experience. The sub-contractor at the job site was2296 Skanska Infra.

"The combination of column stabilisation and mass stabilisation was the only way this area could be developed, as the soft clay can reach down to 18m on this area," explains development manager Ville Niutanen from Biomaa, who is also in charge of the project.

The material being treated was soft peat and clay which in some areas was very wet indeed (the top layer down to 3m was peat and after that the soft layer of clay started). The clay layer can be from 3-18m deep until the solid rock or moraine starts. The layer of clay was column stabilised and the peat layer was treated with mass stabilisation after the column stabilisation was done.

"The mass stabilisation done on top of column stabilisation ensures a surface that does not sink," Niutanen says.

The job started by removing stumps and roots, then a layer of fine sand was spread on top of the surface (approximately 150kg/m3) to improve the quality of the peat so that it stabilises better. On top of this a layer of crushed stone was placed to ensure that the column stabilisation machine moved over the location. The column stabilisation was carried out first through the clay layer to the rock or solid bottom. The columns end at the base of the peat layer, about 3m deep.

When the column stabilisation was completed the crushed stone layer was removed and the pre-mixing of the peat layer was started. In premixing, the fine sand was mixed with the peat, and after the peat was stabilised by feeding and mixing the binding agent evenly to the material.

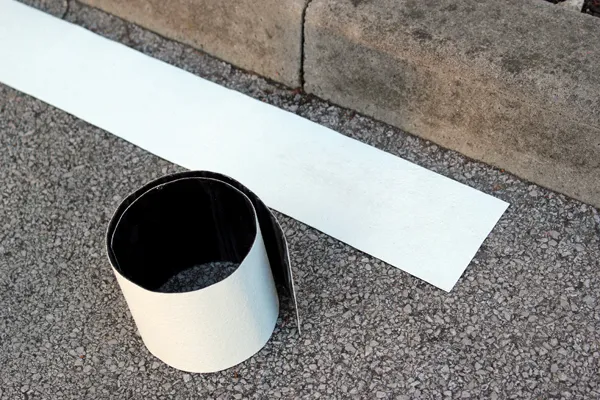

The already stabilised layer was then covered with geotextile and about 100cm layer of crushed stone was placed on top as a preload embankment.

The binding agent used at the job site was cement. In column stabilisation the volume of binding agent was about 130kg/m3 and in mass stabilisation about 100kg/m3.

Depending on circumstances, in one day 800-1,000m3 was mass stabilised using one ALLU unit. The new ALLU PFM 10+10 pressure feeder was in use, and this can feed the binder as far as 200m from the trailer. Part of the time two ALLU PF 7 pressure feeders also worked at the site adding to the capacity.

"It was easy to bring the ALLU PFM to the job site and it saved a lot of time and money, because we did not have to build a road for it at the area where we needed to stabilise, says Niutanen.

The Kivikko industrial area in Finland, which is owned by the City of Helsinki, has expanded gradually over the years and it has expanded again with the new stabilised area now about 3.5hectares.

The

Lead contractor for the Helsinki job, Biomaa from Nurmijärvi, Finland, has many years of stabilisation experience. The sub-contractor at the job site was

"The combination of column stabilisation and mass stabilisation was the only way this area could be developed, as the soft clay can reach down to 18m on this area," explains development manager Ville Niutanen from Biomaa, who is also in charge of the project.

The material being treated was soft peat and clay which in some areas was very wet indeed (the top layer down to 3m was peat and after that the soft layer of clay started). The clay layer can be from 3-18m deep until the solid rock or moraine starts. The layer of clay was column stabilised and the peat layer was treated with mass stabilisation after the column stabilisation was done.

"The mass stabilisation done on top of column stabilisation ensures a surface that does not sink," Niutanen says.

The job started by removing stumps and roots, then a layer of fine sand was spread on top of the surface (approximately 150kg/m3) to improve the quality of the peat so that it stabilises better. On top of this a layer of crushed stone was placed to ensure that the column stabilisation machine moved over the location. The column stabilisation was carried out first through the clay layer to the rock or solid bottom. The columns end at the base of the peat layer, about 3m deep.

When the column stabilisation was completed the crushed stone layer was removed and the pre-mixing of the peat layer was started. In premixing, the fine sand was mixed with the peat, and after the peat was stabilised by feeding and mixing the binding agent evenly to the material.

The already stabilised layer was then covered with geotextile and about 100cm layer of crushed stone was placed on top as a preload embankment.

The binding agent used at the job site was cement. In column stabilisation the volume of binding agent was about 130kg/m3 and in mass stabilisation about 100kg/m3.

Depending on circumstances, in one day 800-1,000m3 was mass stabilised using one ALLU unit. The new ALLU PFM 10+10 pressure feeder was in use, and this can feed the binder as far as 200m from the trailer. Part of the time two ALLU PF 7 pressure feeders also worked at the site adding to the capacity.

"It was easy to bring the ALLU PFM to the job site and it saved a lot of time and money, because we did not have to build a road for it at the area where we needed to stabilise, says Niutanen.