Chicago Pneumatic (CP) has unveiled its comprehensive new concrete equipment range. In applications from walls to floor slabs, the range has products to cover every step of the job, from vibration and levelling to finishing and cutting.

Freshly poured concrete has air voids which must be removed by vibration to increase its density and finished strength. Depending on the concrete’s depth and slump, this can be achieved using a poker or screed. Customers can now choose mechanical, electric or pneumatic p

May 14, 2014

Read time: 3 mins

Freshly poured concrete has air voids which must be removed by vibration to increase its density and finished strength. Depending on the concrete’s depth and slump, this can be achieved using a poker or screed. Customers can now choose mechanical, electric or pneumatic pokers from CP to best meet their specific application and concrete type.

The new durable and user-friendly VPM mechanical pokers are ideal for mid-sized construction sites using medium-to-high slump concrete. VPE electric pokers are ideal where low noise, low maintenance, light pokers are required. They offer fast start-up, a wide action radius and rapid acceleration for medium-to-high slump concrete. For jobs of any size with low-to-high-slump concrete requiring high-speed vibration, the VPP pneumatic poker range delivers high-performance centrifugal force. With compressed-air cooling and low maintenance, these pokers are said to be highly dependable even in the most remote locations.

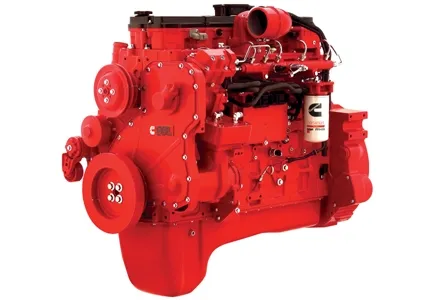

The CP poker range is fully complemented by a wide selection of portable power sources. Mechanical pokers have a choice of gasoline or diesel drive units with rugged construction, rubber mountings to reduce vibration and noise, and quick-release couplings.

CP’s new concrete product line includes walk-behind screeds that provide a consistent, even surface without any guide or supporting tube. Equipped with reliable

Screeding time, labour and transport costs can also be cut with the CP CombiForm lightweight, leave-in-place screed rail system. CombiForm is easily prepared and cast into the concrete, providing an efficient levelling solution.

CP’s STG power trowels are ideal where smoother finished surfaces are essential. The STG 24 is a small power float edger intended for smaller slabs and finishing edges, especially in confined spaces and by walls. STG 36 and 46 are higher capacity trowels designed for larger slabs.

Completing the range are concrete and asphalt floor saws that deliver a straight, stable cut for expansion joints, to a maximum depth of 15cm. They can also cut asphalt for road maintenance, or act as a jack hammer alternative.