Fayat subsidiary SAE is offering a novel cold mix system that is said to offer extra versatility for asphalt plants. The system is said to be adaptable for any plant installation, as long as there is sufficient room.

A spokesperson for the firm said, “It can be implemented on any asphalt plant from any manufacturer and that has any software.” The unit can allow a conventional asphalt plant to produce a quality cold mix, but at a much lower cost than a dedicated cold mix plant. The spokesperson said, “It’s a very compact design and fits inside a standard shipping container.”

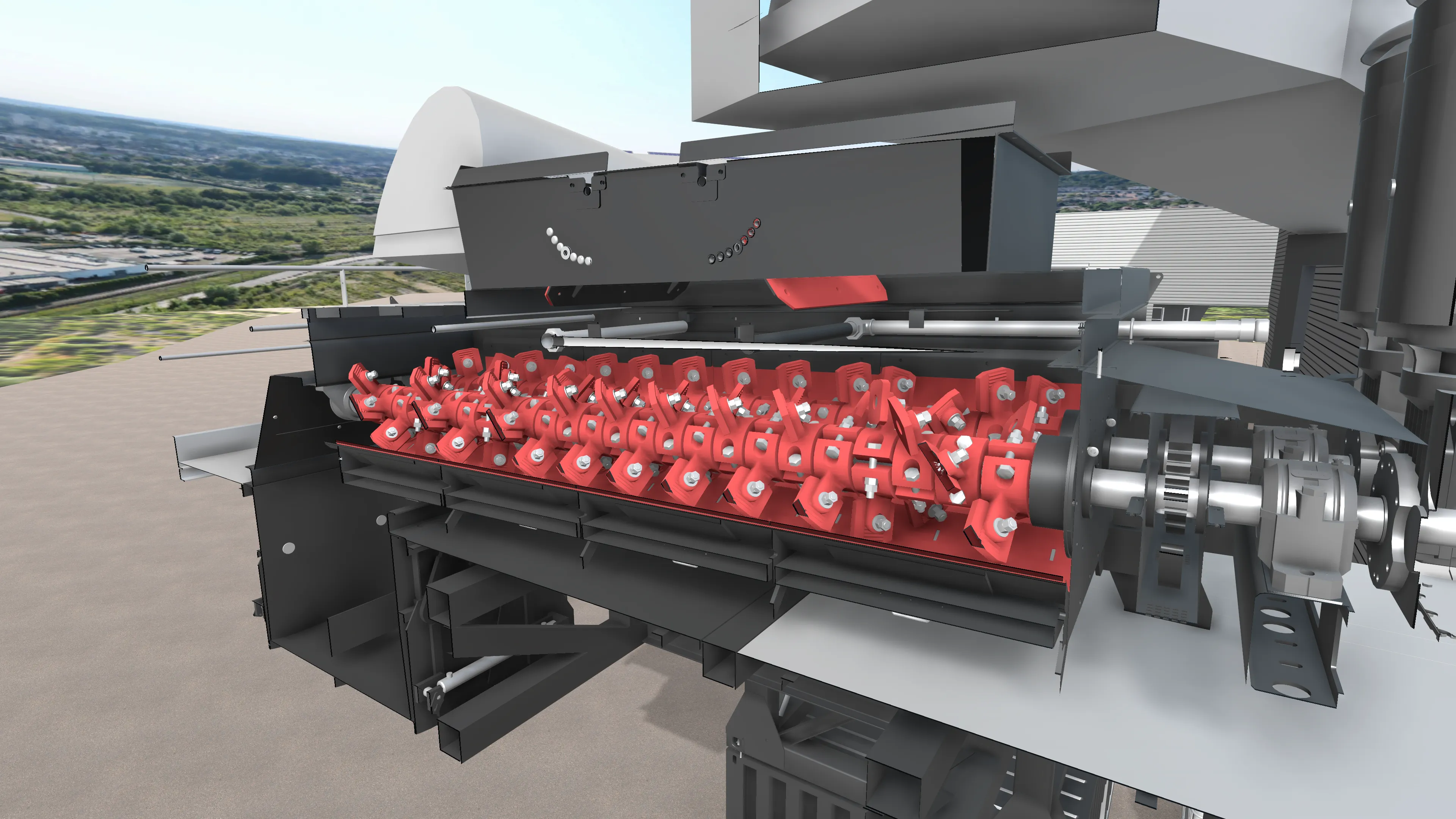

The plant is said to be highly versatile and can use virgin materials or high percentages of RAP in the feed. Water injection, different binders and a range of additives can be used to suit the materials and application. By positioning the pugmill next to the plant, this makes the system easier to handle according to SAE and output can be up to 200tonnes/hour. SAE also says that this plant can help producers meet targets on decarbonising their operations. The spokesperson commented, “By definition it is decarbonised because there’s no heating.”