Melbourne winters are known as some of the coldest of all state capital cities on Australia's mainland, and its summers can be brutally hot. As a result, roads in the region need to be regularly maintained to ensure safety and promote longevity. Pioneer Road Services, headquartered in Victoria, recently took delivery of the first Cat AP300 asphalt paver to Australia, and it will be the first to play a role in maintaining the city's roads throughout the seasons. With the help of Cat dealer William Adams and

July 16, 2012

Read time: 2 mins

Melbourne winters are known as some of the coldest of all state capital cities on Australia's mainland, and its summers can be brutally hot. As a result, roads in the region need to be regularly maintained to ensure safety and promote longevity.

Pioneer Road Services, headquartered in Victoria, recently took delivery of the first Cat AP300 asphalt paver to Australia, and it will be the first to play a role in maintaining the city's roads throughout the seasons.

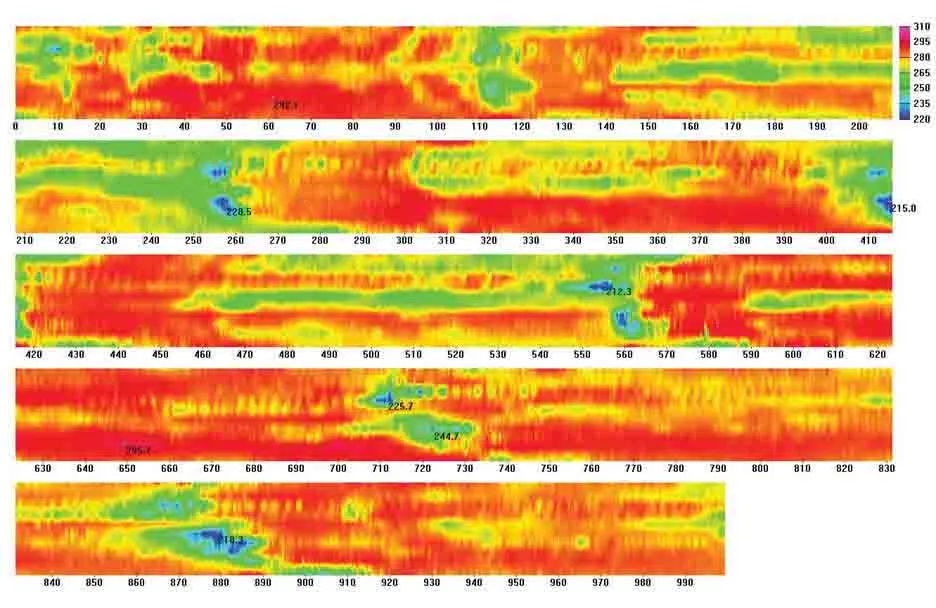

With the help of Cat dealer William Adams and the178 Caterpillar commissioning team, Pioneer Road Services put the new paver finisher through its inaugural paces on an important shoulder reconstruction project for an 8km stretch of highway between Pakenham and Drouin, southeast of Melbourne.

According to the paving crew on site, the project was challenging. Traffic control was critical, as the road was busy and space was at a premium. With the project's narrow paving width, machine productivity and manoeuvrability were critical. Pioneer Road Services knew the powerful, yet small, Cat AP300 with electric screed (model AS3173) would fit the bill, as crews raced to resurface the shoulders of the busy highway in preparation for the approaching winter.

Available in both LPG and electric heating systems, the hydraulic power extendable AS3173 screed offers variable frequency tamper or vibrators, and lays material to the desired depth and width. With mechanical extensions added to both sides, its maximum paving width can reach 4m.

Pioneer Road Services, headquartered in Victoria, recently took delivery of the first Cat AP300 asphalt paver to Australia, and it will be the first to play a role in maintaining the city's roads throughout the seasons.

With the help of Cat dealer William Adams and the

According to the paving crew on site, the project was challenging. Traffic control was critical, as the road was busy and space was at a premium. With the project's narrow paving width, machine productivity and manoeuvrability were critical. Pioneer Road Services knew the powerful, yet small, Cat AP300 with electric screed (model AS3173) would fit the bill, as crews raced to resurface the shoulders of the busy highway in preparation for the approaching winter.

Available in both LPG and electric heating systems, the hydraulic power extendable AS3173 screed offers variable frequency tamper or vibrators, and lays material to the desired depth and width. With mechanical extensions added to both sides, its maximum paving width can reach 4m.