Effective joint heating

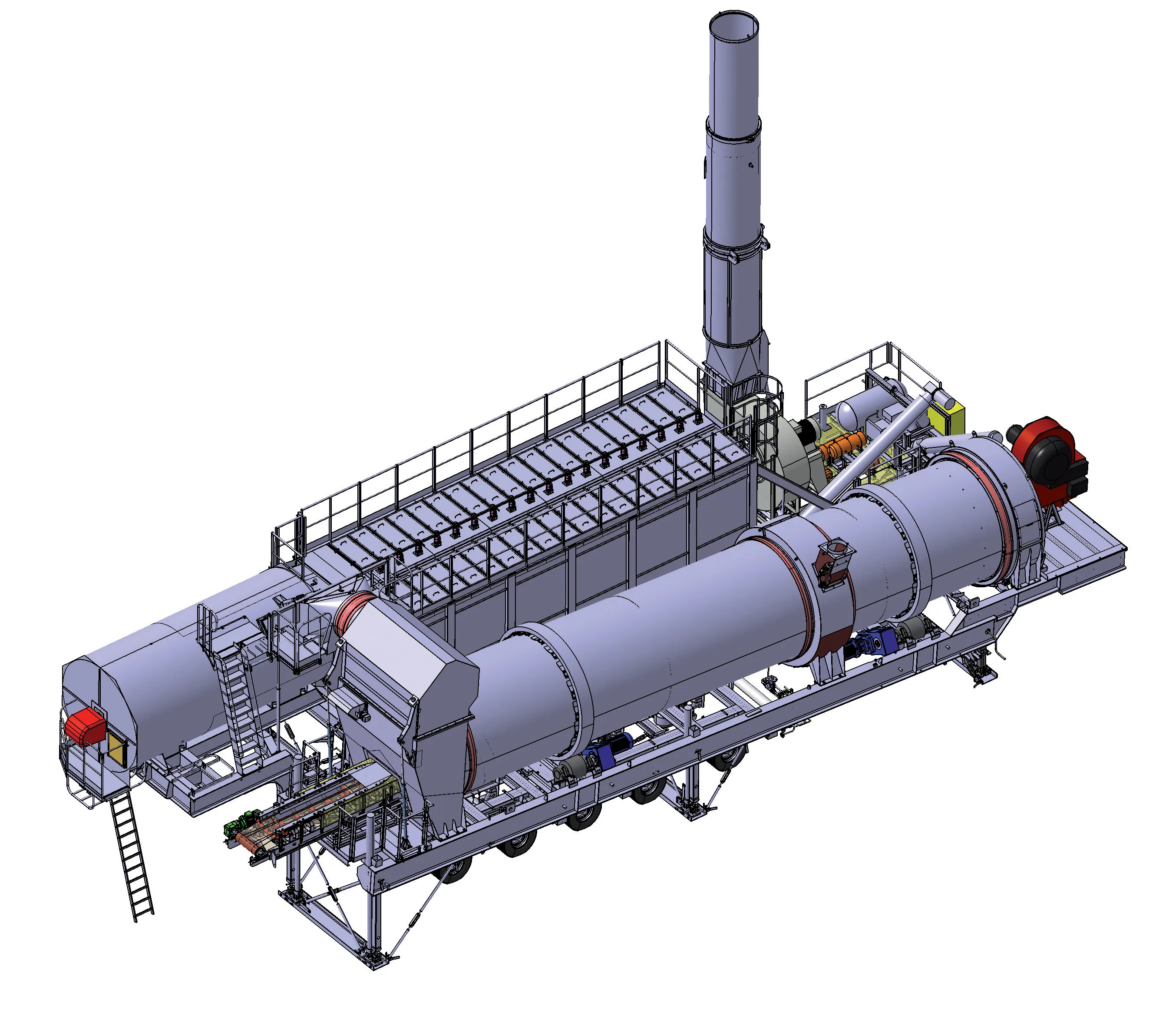

Heat Design Equipment (HDE) has introduced updated versions of two of its successful products, the HDE 750 2TMT asphalt maintenance trailer and the HDE JMH 500-PA asphalt joint heater. The asphalt maintenance trailer heats up and softens an area of asphalt, allowing it to be reworked and repaired.

October 3, 2014

Read time: 1 min