Volvo CE has unveiled a radical approach to asphalt compaction.

By MJ Woof

September 30, 2021

Read time: 2 mins

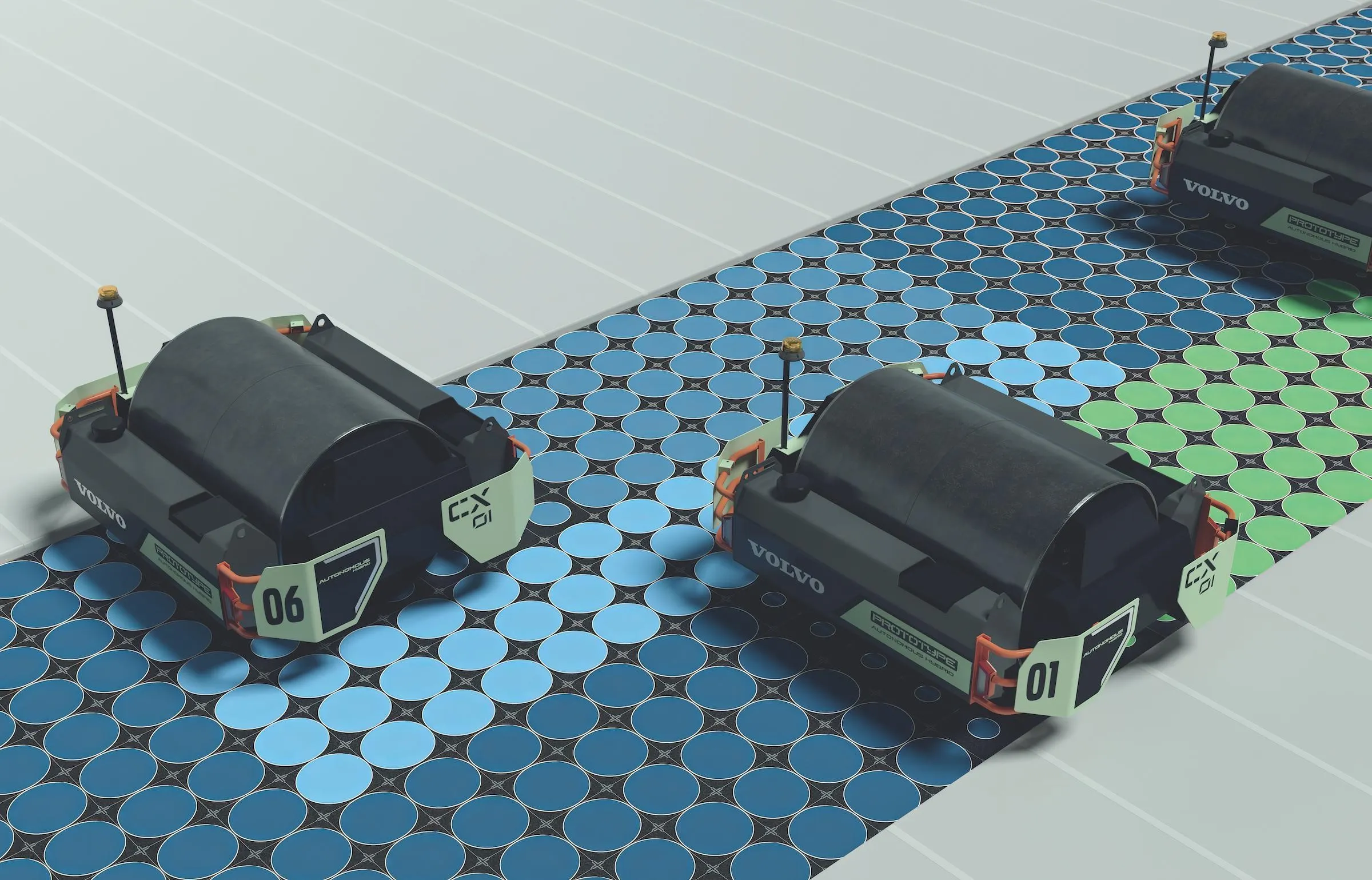

Volvo CE is offering a radical solution to asphalt compaction in the shape of its CX01 concept machine, unveiled recently at the Utility Expo in Louisville, Kentucky.

Although the machine is only a concept design at the moment, this driverless single drum compactor suggests a direction this category of machine design could take in the future. The machine is designed to be either autonomous or operated remotely and features a split drum, allowing it to manoeuvre, while it is also self-balancing.

Power comes from a hybrid drive featuring both a diesel engine and an electric motor and battery pack. The firm says the machine can be driven by diesel, hybrid or all-electric power, depending on the application.

The design is the latest from the firm’s Concept Lab, which has developed various advanced construction machinery types to meet anticipated demands from industry. According to Volvo CE, the CX01 machine would remove the operator from the machine and the working environment.

A single operator could oversee the running of a number of machines working alongside an asphalt paver, boosting the efficiency of compaction operations and achieving higher productivity as well as quality. The firm says that the rolling pattern, number of compactors and working weight could all be optimised to suit the layer thicknesses, mat width and paving speed.

Machine location would be determined using GPS technology. Another novel feature is the design of the low friction drum, intended to minimise water use while also addressing the problem of material sticking to the drum surface.

For the moment this machine remains a concept but as has been seen from previous designs developed by Volvo CE’s Concept Lab, such as the autonomous electric haulers, there is potential for much of the technology to be used in actual working prototypes.

This is not the first autonomous asphalt compactor to be proposed however. Both BOMAG and Hamm have been carrying out tests of their respective prototype autonomous compaction machines for some time.

With a shortage of operators being reported across the construction industry worldwide, increased use of autonomous machines could help address many of these issues.