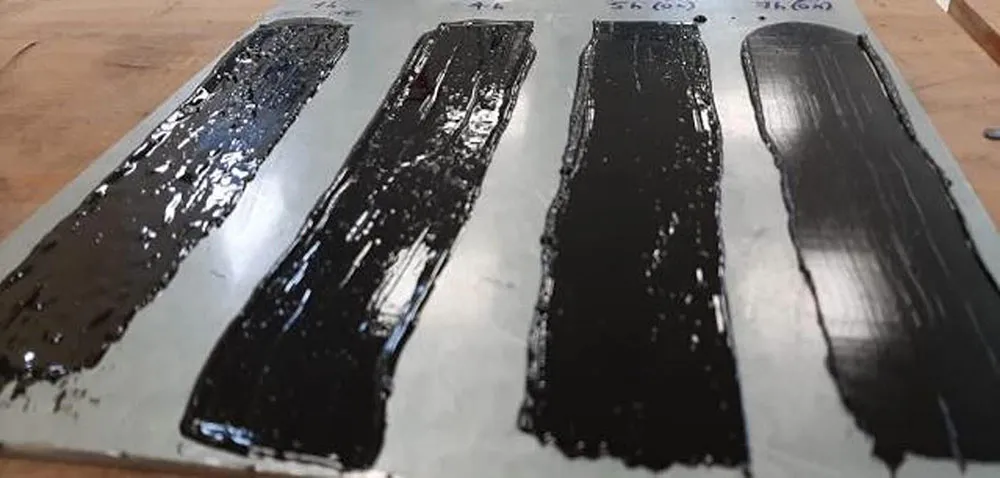

Materials supplier Hanson plans to scale up hydrogen-fuelled net-zero asphalt production at its Criggion asphalt plant in Wales under a UK government demonstration project.

Last year, the Department for Business Energy and Industrial Strategy awarded the consortium Bay Hydrogen Hub – Hydrogen4Hanson project, in Lancashire, England, around US$500 million for a feasibility study. The EDF-led consortium, in which Hanson is a member, will use technology which uses nuclear-generated heat and electricity to create hydrogen for asphalt and cement sites.

The consortium, which also includes National Nuclear Laboratory (NNL) and Vulcan Burners, will match the government’s funding. The hub’s pilot project aims to use nuclear-power-derived hydrogen from Heysham 2 Power Station in the English county of Lancashire to replace the mix of fossil fuels currently used in asphalt production at Hanson’s Criggion plant in Wales. The trial could be running by next year.

The hydrogen will be created by diverting small quantities of electricity and steam from the nuclear power generation process at Heysham 2, via the construction of a solid oxide electrolysis cell (SOEC) electrolyser. Modern high-capacity tankers will transport the hydrogen for use as a fuel at Criggion.

“Nuclear power derived hydrogen has the potential to be a complete game-changer for decarbonising asphalt and cement production,” said Simon Willis, chief executive of Hanson UK. “Our involvement in the Bay Hydrogen Hub project underscores our commitment to lead the way by investing in cutting edge technologies to prove they can deliver in real-world situations and help us meet our net-zero goals.

“Hanson has already successfully shown that hydrogen can be used as part of a net-zero fuel mix at our cement works in Ribblesdale, Lancashire. But its use as a fuel at an asphalt site has not yet been physically demonstrated anywhere in the world,” said Willis.

Initially work will focus on developing a final design for the hydrogen production, distribution and end-use technology. Switching fuel to net-zero hydrogen asphalt production at Criggion will follow.

Hanson UK, part of Heidelberg Materials and a supplier of heavy building materials to the construction industry, is split into four business lines – aggregates (crushed rock, sand and gravel), concrete, asphalt and contracting and cement.