The equipment, which allows asphalt to be laid seamlessly, eliminates joints from the outset. The latest version of the paver-mounted pavement heater from

In TRR’s original system this was a manual process, explains Aidan Conway, a founder of the small start-up company in northwest England. It was very difficult to accurately determine the exact moment to cut off the heat. The answer has been to automate the process.

Once the surface reaches a specified temperature heat is automatically dispelled through fans, maintaining a high-quality surface finish and averting damage caused from over-heating. The paver continues to advance only once the ground temperature has reached an optimum level again.

The concept for the company was initiated in 2012 following

The company spent two years researching and developing the system and since launching the first machine in 2014 it has expanded our portfolio to ensure joints are completely eradicated in asphalt surfaces, whether TRR machines are being used to patch a pothole or when laying an entire carriageway or runway.

Aidan Conway explains further:

How long does it take to reach operating temperature?

“Around one minute depending on ambient temperatures and the type of material being heated. Just as important is the unit's ability to dissipate heat in the event of the cessation of the forward motion of the paver. This fundamentally protects the road surface.”

What temperatures does it reach?

“The unit can emit heat up to 500°C. However, the sensors match the forward pace of the heater with desired joint temperature. If the system exceeds a desired pre-set temperature on the joint, the heat backs off automatically. The unit produces consistently heated material at a controlled temperature going into the screed. The way our system transfers heat into asphalt results in temperature retention in the material through compaction.”

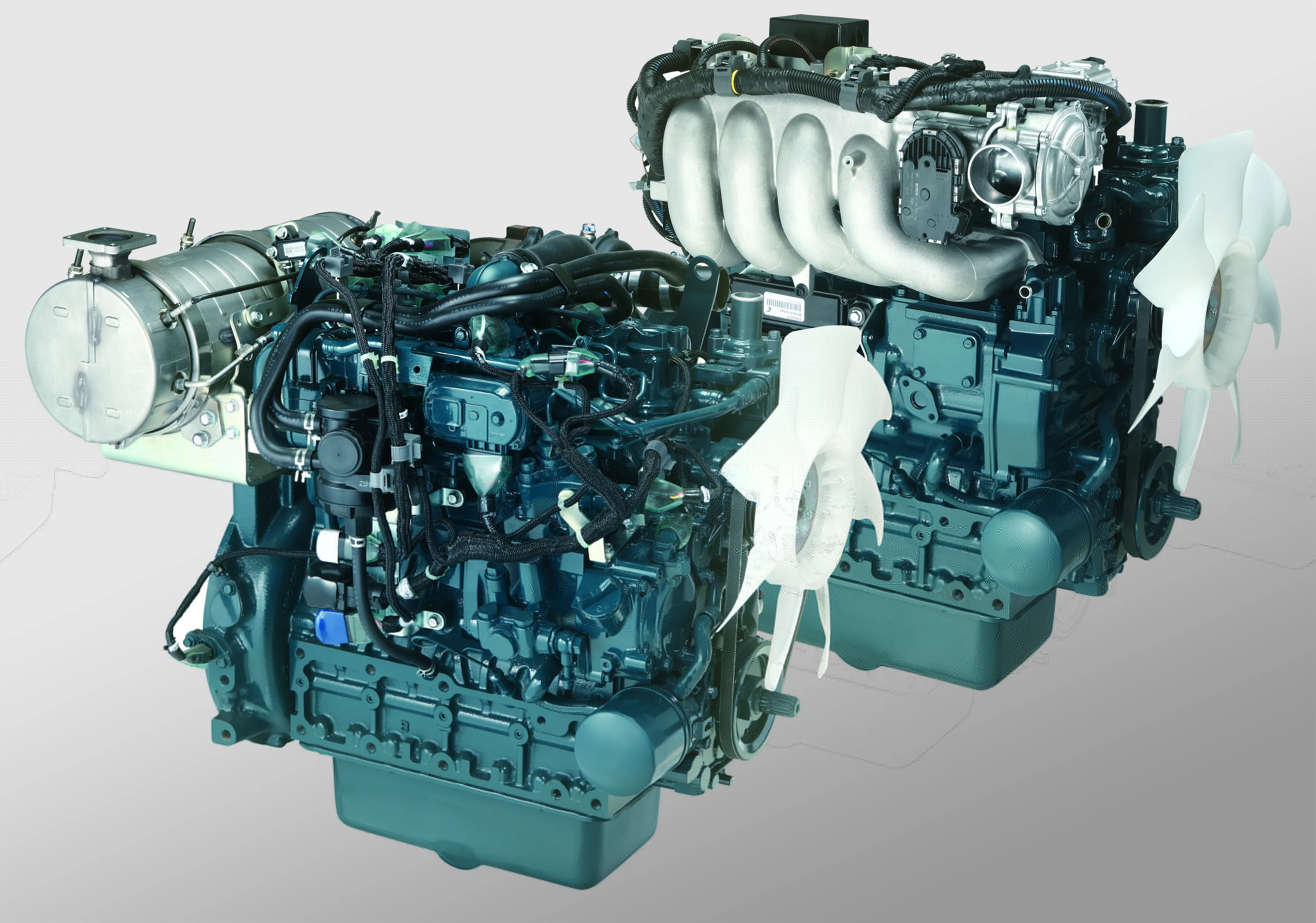

How much does it weigh?

“The unit itself weights 68kg and is fully demountable. It fits onto a specially-made mounting bracket on the paver and doesn’t affect normal operations around the paving machine.”

“LPG [liquefied petroleum gas; called Autogas, GPL and GLP in some European countries].”

How long does it take to mount on a machine?

“Average of five minutes.”

What special provisions are needed when installing it on a machine?

“None, other than the mounting of the bracket and provision of gas. Further to this,

How long does it take to heat up the joint area?

“Around one to two minutes, depending on ambient temperature. More importantly, there is no impact on laying speeds so operational output is not negatively affected.”

How long will it take to make a return on the investment?

“The unit cost would depend on paver make and model but would include our stop/start synchronisation system. Return on investment is short as no other joint treatments such as modified bitumen, emulsion or cold pour materials are required. The true cost is insignificant compared to a failed joint.”

Can customers either rent or buy the unit?

“Customers can rent, lease or buy. Our UK customers which have them already installed include Tarmac National Contracting, Associated Asphalt, Breedon Contracting, Colas, Lagan Construction, Gibbs Surfacing and Thomas Bow City Asphalt.”