A substantial investment in new Hitachi Construction Equipment machinery is said to have enhanced productivity for the largest aggregates quarry in Cyprus. The Skyra Lima Public Ltd site relies on Hitachi ZW wheeled loaders – supplied by Cypriot Hitachi dealer Unitrak Machinery Ltd – to cope with the tough conditions on the Mediterranean island. The 40-hectare quarry is situated beside the Stavrovouni Monastery – located on the mountain peak of the same name – near the villages of Kornos and Pyrga. It was i

October 30, 2012

Read time: 3 mins

A substantial investment in new 233 Hitachi Construction Equipment machinery is said to have enhanced productivity for the largest aggregates quarry in Cyprus. The Skyra Lima Public Ltd site relies on Hitachi ZW wheeled loaders – supplied by Cypriot Hitachi dealer Unitrak Machinery Ltd – to cope with the tough conditions on the Mediterranean island.

The 40-hectare quarry is situated beside the Stavrovouni Monastery – located on the mountain peak of the same name – near the villages of Kornos and Pyrga. It was initiated in 1960 and bought by Skyra Lima Public Ltd 14 years later. Skyra Lima was taken over by the Iacovou Group in 2006 and since then it has made some significant changes to the management of the diabase quarry. These have included the introduction of a primary crusher, a mobile crusher, six trucks and a Hitachi ZW550 wheeled loader. The new equipment is said to have helped to almost double production from 1.2million to 2million tonnes per annum within two years.

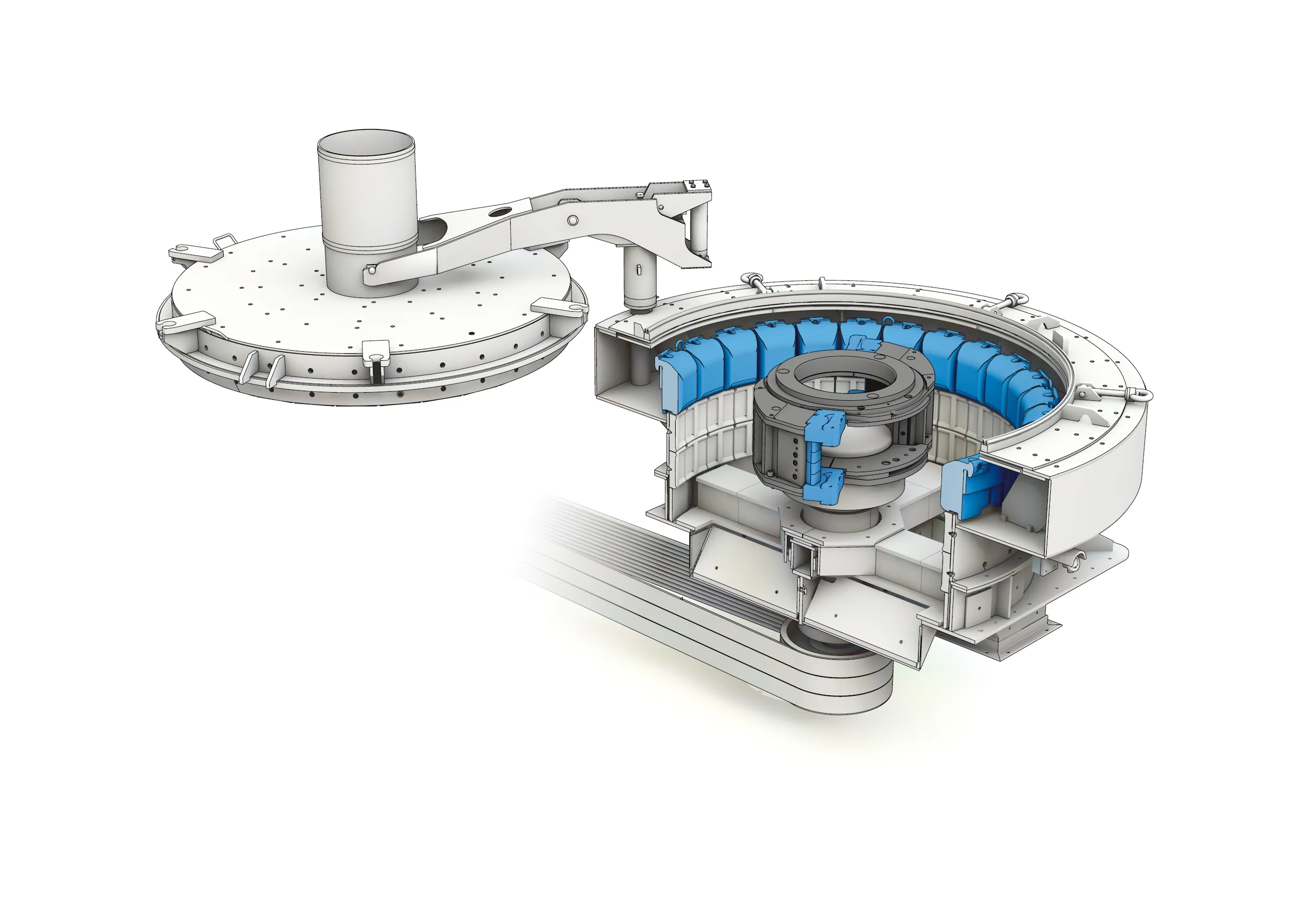

“We blast the rock four or five times a week with a mix of dynamite and ANFO,” said Skyra Lima’s quarry manager, Iakovos Stefanou. “The ZW550 is then used to load five of our trucks, which transport the materials over a distance of 1.5km and dump them into the primary crusher. This feeds two production plants, which have three and five cone crushers respectively.” Both production facilities output the same grades of aggregates: 0-4, 4-10, 8-20 and 10- 14mm for the asphalt and concrete markets; and 0-32, 10-32 and 0-70mm of sub-base for road construction sites. The company’s asphalt and concrete customers are also described as its largest, and they collect the materials directly from the quarry.

Skyra Lima’s second Hitachi wheeled loader, a ZW310, loads the constant stream of trucks that arrive in the stockyard from early morning. The 41-strong team work from 7am until 3pm in the quarry, and in two shifts, from 7am to 3pm and 3 to 9pm, in the production plants.

The ZW310 was delivered in December 2007 and has completed over 10,000 working hours. “It has been operating perfectly and the fuel consumption is also favourable compared to other machines,” said Stefanou.

“The success of the ZW310 led to the purchase of the ZW550 in February 2011. We use the new wheeled loader – rather than a large excavator – for loading the rock, due to its excellent mobility and reduced running costs. It is fast, stable and has a strong chassis – ideal for manoeuvring up and down the 11 benches in the quarry.

“It also has a high penetration force and takes around one minute and 45 seconds to fill each truck. At ten tonnes per pass, this equates to 450 tonnes per hour. The Hitachi wheeled loaders are vital to our operation, as is the maintenance and service supplied by Unitrak.”

The 40-hectare quarry is situated beside the Stavrovouni Monastery – located on the mountain peak of the same name – near the villages of Kornos and Pyrga. It was initiated in 1960 and bought by Skyra Lima Public Ltd 14 years later. Skyra Lima was taken over by the Iacovou Group in 2006 and since then it has made some significant changes to the management of the diabase quarry. These have included the introduction of a primary crusher, a mobile crusher, six trucks and a Hitachi ZW550 wheeled loader. The new equipment is said to have helped to almost double production from 1.2million to 2million tonnes per annum within two years.

“We blast the rock four or five times a week with a mix of dynamite and ANFO,” said Skyra Lima’s quarry manager, Iakovos Stefanou. “The ZW550 is then used to load five of our trucks, which transport the materials over a distance of 1.5km and dump them into the primary crusher. This feeds two production plants, which have three and five cone crushers respectively.” Both production facilities output the same grades of aggregates: 0-4, 4-10, 8-20 and 10- 14mm for the asphalt and concrete markets; and 0-32, 10-32 and 0-70mm of sub-base for road construction sites. The company’s asphalt and concrete customers are also described as its largest, and they collect the materials directly from the quarry.

Skyra Lima’s second Hitachi wheeled loader, a ZW310, loads the constant stream of trucks that arrive in the stockyard from early morning. The 41-strong team work from 7am until 3pm in the quarry, and in two shifts, from 7am to 3pm and 3 to 9pm, in the production plants.

The ZW310 was delivered in December 2007 and has completed over 10,000 working hours. “It has been operating perfectly and the fuel consumption is also favourable compared to other machines,” said Stefanou.

“The success of the ZW310 led to the purchase of the ZW550 in February 2011. We use the new wheeled loader – rather than a large excavator – for loading the rock, due to its excellent mobility and reduced running costs. It is fast, stable and has a strong chassis – ideal for manoeuvring up and down the 11 benches in the quarry.

“It also has a high penetration force and takes around one minute and 45 seconds to fill each truck. At ten tonnes per pass, this equates to 450 tonnes per hour. The Hitachi wheeled loaders are vital to our operation, as is the maintenance and service supplied by Unitrak.”