UK bridge works specialist Spencer Group has been appointed to create an access system for inspecting stay cables on the new Pattullo Bridge in Canada.

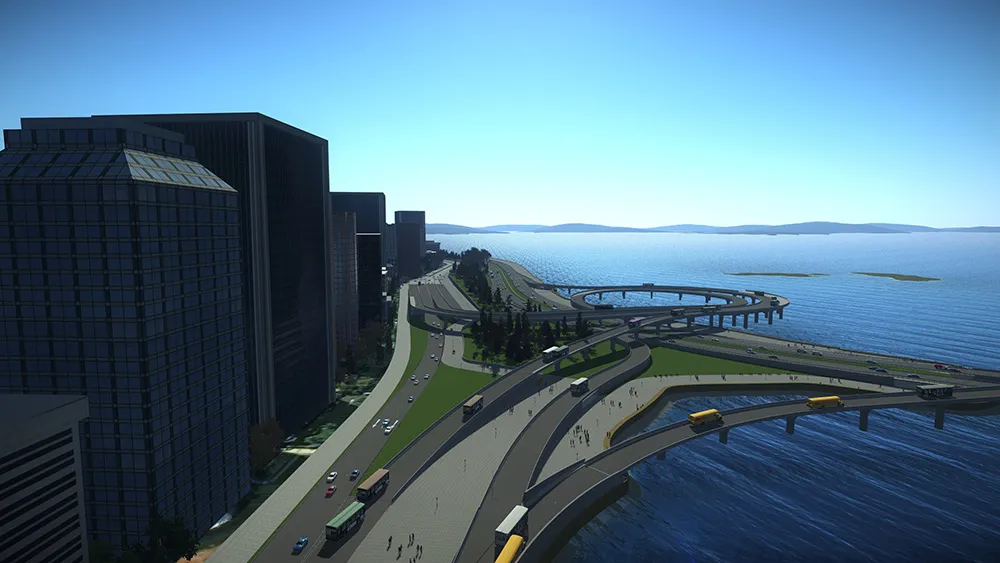

The new bridge is a replacement bridge across the Fraser River near Vancouver, British Columbia connecting the municipalities of Surrey and New Westminster. The new Pattullo Bridge will take over from the existing bridge of the same name be used by drivers, cyclists and pedestrians when it opens in 2024. The existing bridge was opened in 1937 but now ceases to meet modern design standards.

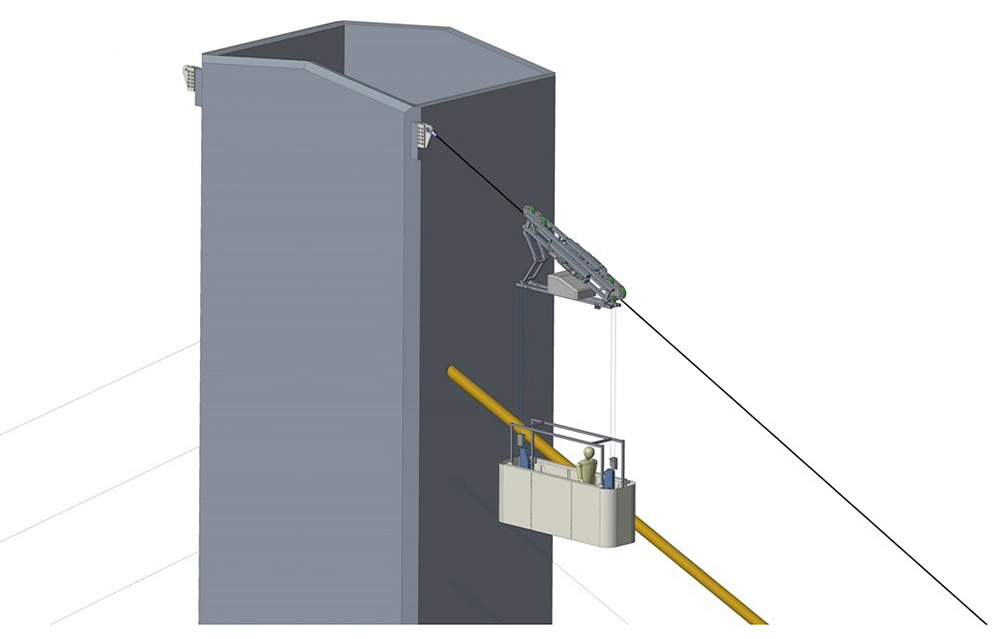

Working on behalf of Fraser Crossing Constructors GP - a 50/50 joint venture between Acciona and Aecon - Spencer Group is designing, manufacturing, testing and commissioning a semi-permanent access system to enable maintenance engineers to inspect all elements of the bridge’s stay cables.

The cradle element, which transports personnel to the desired inspection location, operates similarly to a cable car, moving up and down a track rope on what will be a four lane, toll-free bridge. The cradle will be electrically hoisted up and down the main track rope. It will also vertically move up and down to enable personnel to inspect the stay cable wires throughout the lifespan of the bridge.

Gordon Neilson, principal engineer at Spencer Group and an expert in bridge gantry design, is behind the design for what is being called “The Pattullo Bridge cable fan access system”. Design work is set to be complete by the end of the summer. Manufacturing and testing will take place in the UK before the entire access system is then shipped to Canada for installation.

Fraser Crossing Constructors GP will be designing the bridge to interface with the stay cable access system, before it is tested and commissioned by Spencer Group.

Steven Bunting, project director at Spencer Group, is leading the project and coordinating the various stages of the design and build. “Our unique design on this project will be transferable to other cable stay bridges all over the world. It addresses challenges faced with the need to carry out tactile inspections of cables from a dedicated work platform, at difficult to reach locations at significant elevations,” said Bunting.

The new bridge will provide a safer crossing for bridge users with modern, wider lanes, separated by a centre barrier, dedicated walking and cycling lanes separated from traffic by a barrier on both sides of the bridge.

The bridge was originally to be opened in 2023, but the province decided to push back the opening to 2024 because of the Covid pandemic which disrupted supply lines and work schedules. The existing bridge will remain in use until the new bridge is open to traffic in 2024 but then will be removed.

Transportation Investment Corporation, a provincial Canadian Crown corporation, is delivering and overseeing this CAN$1.377 billion (US$1.05 billion) project. Fraser Crossing Partners is designing and building the new bridge. The province of British Columbia will own and maintain the new bridge when complete.

Spencer Group has carried out maintenance and repair work on some of the UK’s most iconic bridges. This includes major refurbishment on the Menai Suspension Bridge across the Menai Strait between the island of Anglesey and mainland north Wales - ahead of the structure’s 200th anniversary year in 2026.

Spencer Group’s specialist bridges team has global experience in high-level bridge works. It developed the Cable Crawler gantry system to enable vital dehumidification work to prevent corrosion of cables on the Severn, Forth Road and Humber suspension bridges in the UK, as well as the Alvsborg Bridge in Sweden. The company was founded by the now executive chairman Charlie Spencer in 1989 and is headquartered in Hull, northern England.