Drivewyze, which provides safety and services for connected truck operations, said that its notification service first became available for free to Drivewyze customers at seven mountain pass locations in the state of Colorado last month. Other states now with the service include Arizona, California, Idaho, Massachusetts, New Mexico, Nevada, New York, North Carolina, Tennessee and West Virginia.

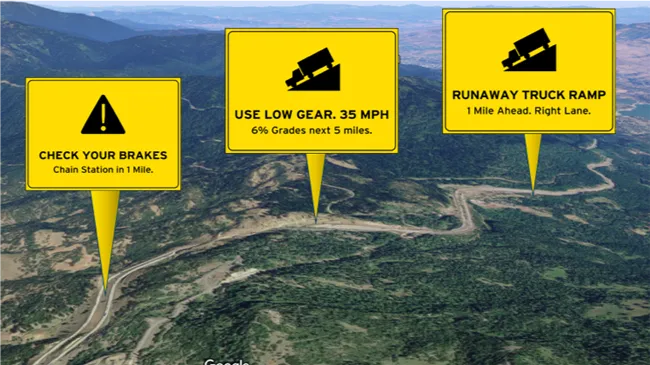

With the alerts, Drivewyze subscribers have their drivers receive in-cab alerts of upcoming safe locations to pull over for brake check inspections. They also see prompts for them to gear low, notifications of suggested maximum speed down steep grades and alerts for upcoming runaway ramps, explained Charlie Mohn, product manager at Drivewyze.

“All of the mountain passes include grades of 5% and higher. Our goal is to help drivers focus on the terrain ahead while providing information that will make them safer on the road,” said Mohn.

According to Mohn, I-64 near Beckley in West Virginia, which is the longest 7% grade in the US is included in Drivewyze’s mountain corridor safety alerts. Other difficult passes included are I-26 in North Carolina near the North Carolina and Tennessee border, southbound I-15 by Baker Pass in California and I-80 by Donner Pass in California, notorious for its nearly 65km westbound descent from the summit.

Drivewyze also manufactures the PreClear weigh station bypass service which continues to be the US company’s main business. Both PreClear the safety notifications service are available to carriers on supported ELDs (electronic logging devices) and other in-cab devices. Connection is through the %$Linker:

Drivewyze PreClear subscribers now receive bypass opportunities at more than 800 locations in 45 US states and Canadian provinces.