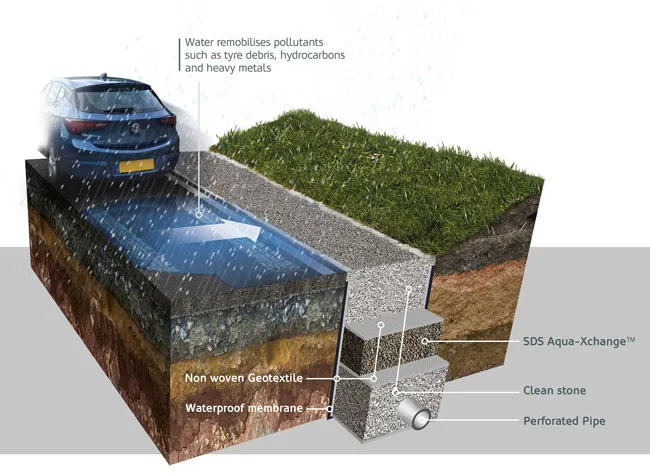

Delivered to site in lightweight 1m³ bags, it can be deployed as stormwater treatment in highways drainage, as well as on other higher risk locations such as retail car parks, freight and logistics hubs.

SDS claims that independent tests have shown its Aqua-Xchange removes 99% of dissolved copper and zinc, toxic metals identified by Highways England as priority pollutants and subject to strict regulatory controls.

Aqua-Xchange was also proven to retain these metals even when applications of road salt were simulated.

It works through a combination of naturally-occurring materials that use adsorption and ionic exchange to form unbreakable bonds with the heavy metals. It captures and retains them even in heavy storms.

The result is “an affordable and truly versatile new SuDS material that can be used in both existing and new drainage schemes”, according to Jo Bradley, SDS market development manager and who led the development project.

Aqua-XchangeTM has a large active surface area, enabling high-performance pollutant removal in a small space. As a result, it can be used to deliver pre-treatment as part of a vegetative SuDS scheme, enabling smaller SuDS ponds or wetlands to be designed where otherwise there would have been no room for them.

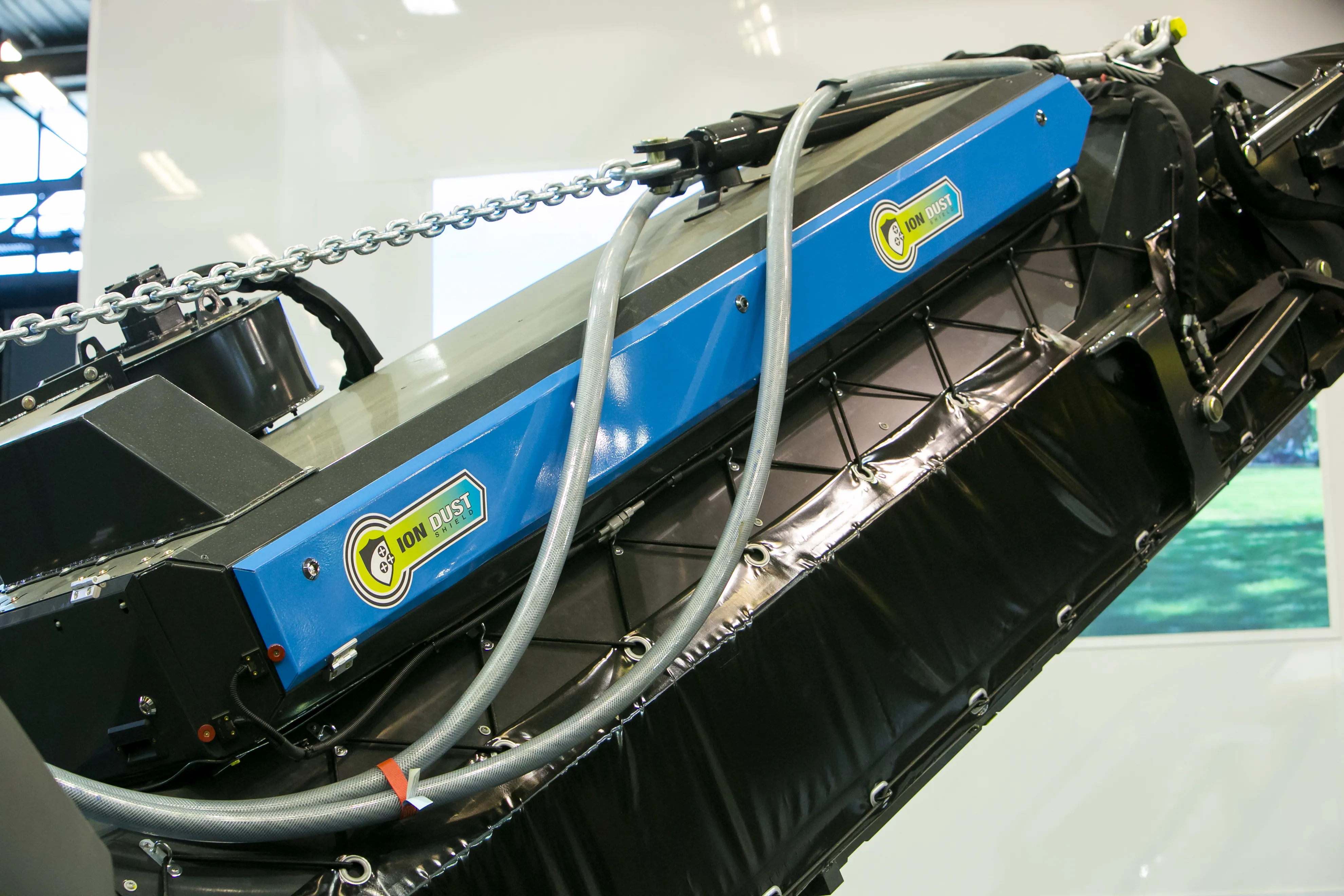

In a typical application, a layer of SDS Aqua-Xchange can be added as an additional component to a linear filter drain and can be installed at a shallow depth which avoids costly excavation and use of heavy cranes.

The SDS Aqua-Xchange can also be combined with other proprietary SuDS devices. As it can filter out finer silts and sediments, it can be deployed downstream of a hydrodynamic vortex separator such as SDS’s Aqua-Swirl that targets larger particles. It can also be combined with geo-cellular storage, such as SDS’s GEOlight, when additional attenuation is needed as part of a roadside treatment system.

Aqua-Xchange can be included as a component in vegetative SuDS devices such as dry swales, raingardens or bio-remediation zones, so that robust retention of copper and zinc is completely assured while plants can continue to thrive as part of the landscaped design.

The company says that the Aqua-Xchange was tested to reflect a range of rainfall conditions under the observation of an independent representative from a UKAS-accredited laboratory in accordance with the British Water protocol.