Traffic to and from Linz city centre will use the new bridges while motorists wishing to bypass Linz will cross over on the existing bridge.

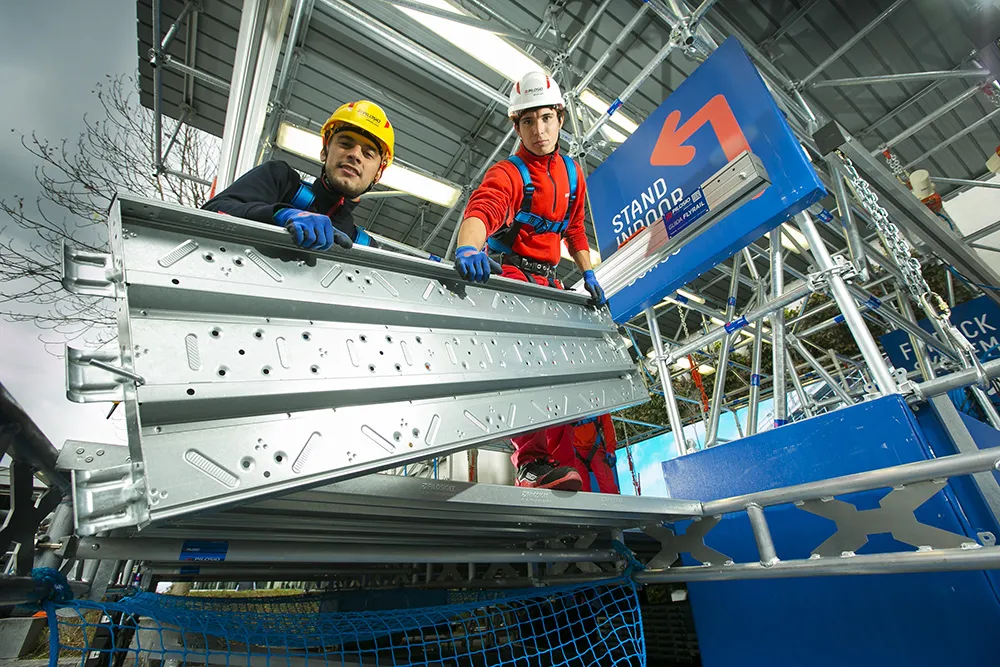

Work started in January 2018. Building four oval piers in the middle of the surging Danube poses a technical and logistical challenge. Sheet pile boxes are used to create dry space for the concreting of the base upon which the piers will be built in two sections. These massive columns are around 15m tall, 4.5m wide and up to 19.7m long. The formwork comprises wooden boxes made of Top 50 elements, assembled by the Doka pre-assembly service.

Exceptionally strong connection lugs are installed to transfer longitudinal anchor loads. This eliminates the need for tie rods on the longitudinal side and through the curves.

The piers are concreted using two types of concrete to provide an outer area that is particularly resistant to the wear caused by the strong flow of the Danube River. Constructing the oval foreshore piers on land is a little easier. Special lugs are also used for the formwork there. The river piers and the oval foreshore piers all have a fine, regularly structured surface as the pier formwork features matrices and trapezoidal bars. Round piers support the numerous entry and exit ramps. Around 20 of these piers measuring 1.2m in diameter are made from RS steel column formwork in a special design. Pre-assembled wooden box formwork made of Top 50 large-area formwork is used for seven piers with a thickness of 2m.

On the Linz waterfront the existing superstructure on both carriageways is being widened by up to 9.5m over 350m. The shoring is provided by a combination of Dokamatic tables with the Staxo 100 load-bearing tower. Where the deck meets the widened support structure, the consortium is building a 165m-long retaining wall including a cantilever slab.

The Top 50 formwork elements are anchored without ground support. Traffic into the city will be separated from through traffic at the Urfahr junction, so various entry slip roads and exits have to be created. A large number of Staxo 100 load-bearing towers are to be used for the superstructure in construction section LZ35D. WS10 multipurpose waling will be mounted to this structure and fitted with H20 top formwork beams and the 3-SO formwork sheet.

The concrete for the 100m-long ramp structure is then poured in one step. The subsequent 250m-long curved passage , the LZ35C, will consist of eight sections with the base slab constructed in advance. The bottom formwork for the box girder cross-sections here sits on a Xervon falsework. Alu Framax Xlife framed formwork is used as the internal formwork for the sidewalls. Top 50 large-area formwork on Staxo 100 load-bearing tower is used for the outside of the sidewalls and the cantilevers.

Doka says that its site team uses special shifting trolleys on castors to enable fast and efficient manipulation of the Staxo units. The sidewalls and deck slab of the superstructure for sections LZ35A and LZ36A are also concreted in one pour along their 100m-length. The steel superstructures over the Danube will link directly to these sections once they are completed. In the coming months, construction sections LZ35B, LZ36B and LZ36C will be constructed as slab superstructures.

Completion of the bridges is set for mid-2020 with the highway upgrades and new-build to be finished in 2023.