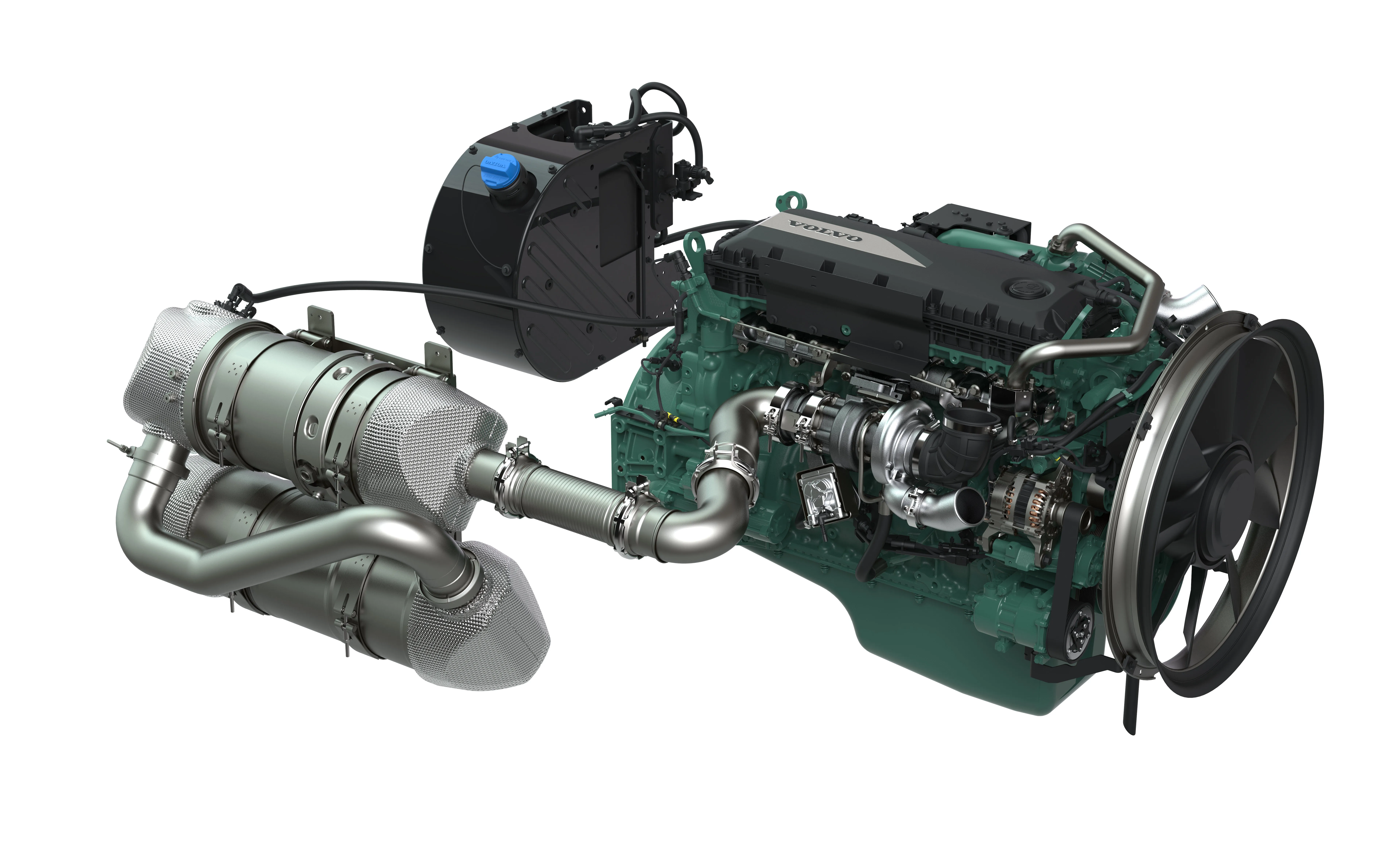

Each power solution features a high-performance engine with matched exhaust aftertreatment system (EATS), to comply with the next EU emissions level. The company says that its Stage V range is optimised to meet future needs and keeps the highest focus on maximised uptime and fuel efficiency, along with ease of installation, operation and maintenance. The range offers power outputs from 105-565kW.

The top-of-the-range unit is the 16litre D16 diesel, which offers a maximum power of 565kW. It is said to be a robust unit with dual-stage turbo charging which provides high power density, low fuel consumption, and a broad power band with full torque from 1000rpm. As with the D16, the D5, D8, D11 and D13 are designed to maximise uptime and ease of installation, operation and maintenance.

Fuel efficiency is achieved with common rail fuel injection and fixed geometry turbo. Effective heat management is reached through the use of an air inlet throttle, together with uncooled exhaust gas recirculation (EGR), and the electrical exhaust pressure governor (EPG). This enables the system to function without the need to inject fuel into the exhaust stream to raise the temperature. With this approach, the exhaust gas has an optimal temperature when it passes through the EATS.

The EATS includes: diesel oxidation catalyst (DOC); diesel particulate filter (DPF; for D5-D13 models); selective catalytic reduction (SCR); and ammonia slip catalyst (ASC).

The D5-D13 Stage V engines and EATS are designed to work together to maximise passive regeneration during normal operation. With Volvo Penta’s Stage V approach, there is no high-temperature regeneration due to the fact that sulphur regeneration in the SCR catalyst is not required; only soot regeneration is needed to clean the DPF.

These engines are also offered for use in market areas with less strict regulations on emissions. The firm says that the versions without the emissions control packages share the same footprint, making it easier for a firm to install the engines in construction machines for global use, without requiring design changes to the equipment.