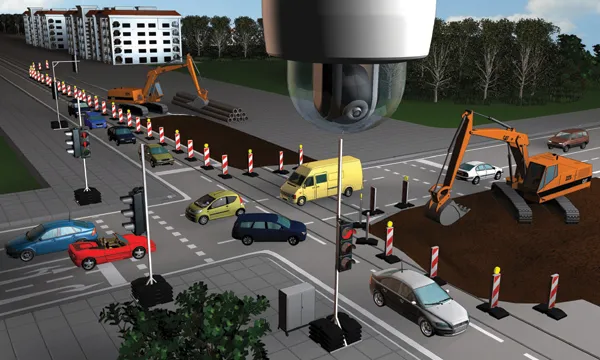

Fabema GmbH is offering a new and more sophisticated solution for monitoring traffic flows, with its FMC-N multi-functional control that can be used during traffic jams, allowing the user to monitor phase changes from a PC. The unit, for both temporary and stationary use, suits installations with traffic signal systems featuring up to 32 signal groups and 256 signal lamps.

February 10, 2012

Read time: 2 mins

The unit, for both temporary and stationary use, suits installations with traffic signal systems featuring up to 32 signal groups and 256 signal lamps.

It can be employed in simple or complex traffic-related installations and meets European requirements.

The system is said to offer easy installation due to its twin wire technology and the package is available with open ring/string wiring or prescribed star wiring. It does not require costly distribution apparatus or mast distributors according to Fabema.

The package features intelligent fully monitored LED signal heads and allows the connection possibility of up to three respective independent detectors, switches, induction loops or cameras. It can be operated as part of a network or can be run independently, with either battery, solar or hybrid power.

Features include graphic software for full traffic-actuated programming, and data transfer can be handled by plugging in a USB stick.

The system allows the creation of traffic-related drawings/documentation in a single operation using its own software, and comes with a touch-screen colour display and allows recording, documentation and printing of procedures and signalling conditions in real time.

Other features include unlimited phase options pre-programmed into the control unit, the capability to work with adjacent signal systems or central computers with communications handled by cable or DCF synchronous time signal and remote monitoring through GSM/SMS or wireless GPRS Internet connection.

Options include GPS data analysis, a public transport and emergency vehicle priority feature and push connectors or series terminals. Meanwhile, the modular design is said to allow fast replacement of units when required, while the system also allows traffic lights to be operated remotely.