Swarco has been well known for excellent variable message sign (VMS) technology for several decades. Countless motorways across Europe and far beyond feature the VMS in numerous project-specific dimensions with either fixed sets of symbols or freely programmable full-colour texts and graphics. Swarco engineers in Austria have now developed a new product that introduces more flexibility, modular design and short delivery and installation times to the market of dynamic signalisation: CubiLED.

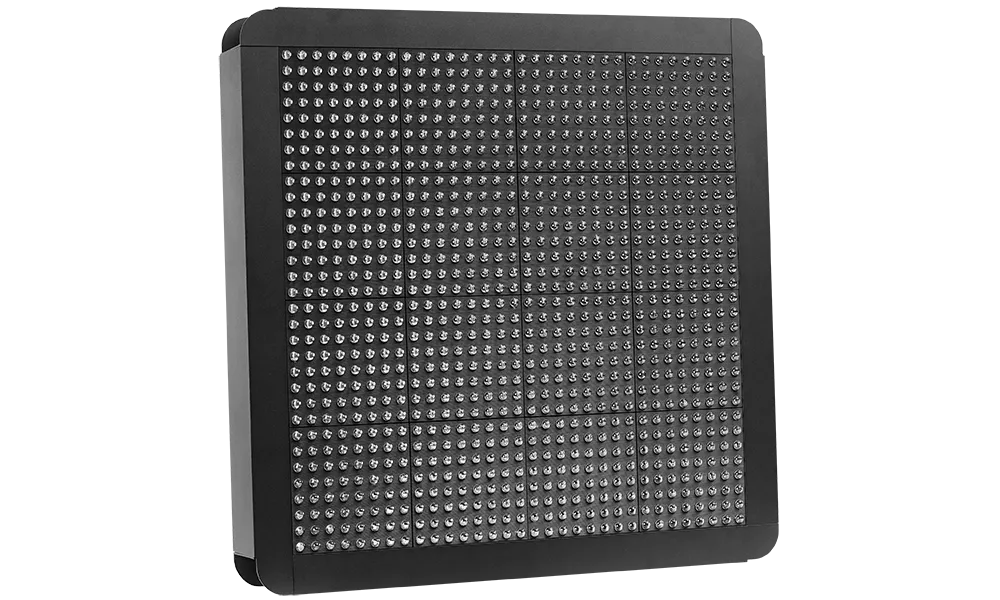

“The idea behind it is that our customers now have the option to compose the LED VMS they need from standardised cubes," explains product manager Armin Peter. “This is particularly interesting for small-scale projects with less complex configurations. The easy scalability of CubiLED allows you to choose the cubes according to the height and width you need. Should you wish to make your VMS bigger one day, just add more CubiLEDLEDs and a new frame".

CubiLED is offered as a standard kit of parts (cubes, frame, controller, cabling) easy to assemble locally due to the practical quick-release fasteners of the cubes. The compact plug-and-play design not only enables on-site installation generating local added value, but also leads to lower transport costs and easy maintainability. The full-colour and fully-graphic cubes have been developed for simple installation and for extending individual LED variable message signs.

CubiLEDs can be used for temporary installations and re-use the parts in a different configuration later on. Of course, the new VMS builds on the patented cutting-edge and highly energy-efficient optic system Swarco customers are used to. This ensures brilliant display over a very long lifetime of the sign. Needless to say, all Swarco CubiLED components comply with the EN 12966 specifications.

Artur Pesendorfer, managing director at Swarco Futurit, hints at further advantages of this modular approach in VMS. “The compactness of the product facilitates storage. That is why we are able to ship CubiLED from our factory in Austria within a week and quickly react to customer-specific requirements, order modifications and new projects. Our customers thus get more flexibility for their own business models and ideas in terms of dynamic signage."

CubiLED Factbox

Light source: Top-quality LEDs from well-known manufacturers

IP protection classes: IP45–IP65

Temperature range: -40 °C to +60 °C

Cube dimensions: 320 × 320 × 100 mm

Pixel pitch: 20 mm

Supply voltage: 110–230 VAC

Power consumption: max. 80 W/m2 / typ. 15 W/m2

Norm: EN 12966:2014 + A1:2019

Sponsored content produced in association with Swarco