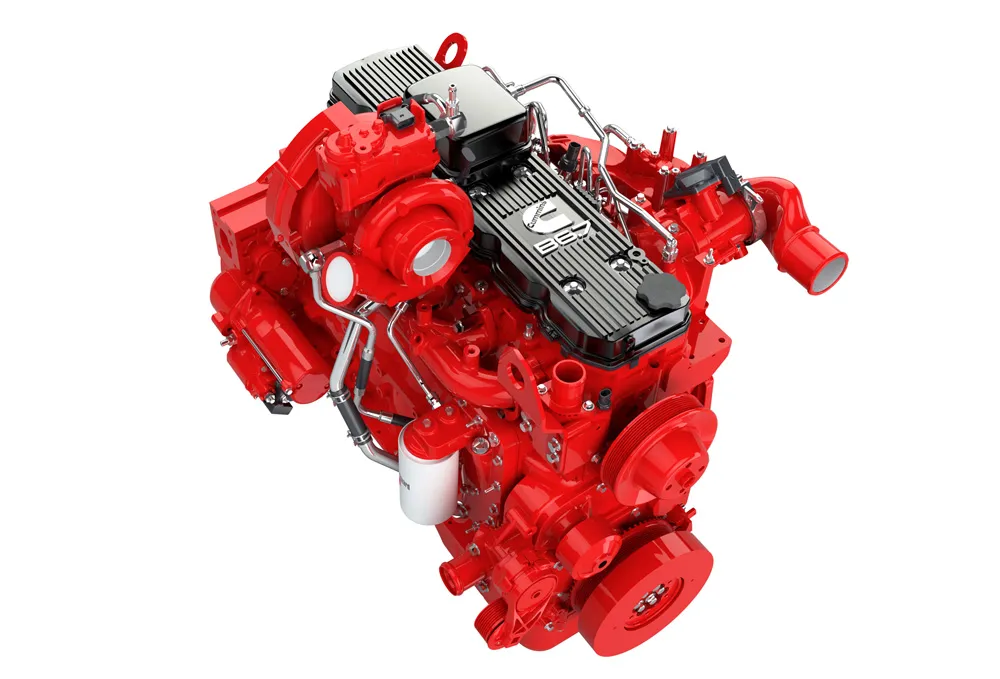

Power comes from a 168kW (225hp)

The machine benefits from a more spacious cab that is 12% wider with larger windows and climate control.

As with all of Soilmec’s rigs, the machine conforms to EN16228 safety standards, even in countries where they are not compulsory.

There is a new rotary head with 6% more torque and a faster crowd system with a 30% faster maximum speed.

The machine can be configured in three variations, to suit friction and locking Kelly use and for CFA. Maximum friction depth is 56.9m, while maximum locking Kelly depth is 45.4. When set up as a CFA rig the machine can drill to a 23m depth.