Using this package, contractors can now schedule and dispatch trucking along with employees, equipment and materials using a centralised, online platform from B2W according to the firm.

New capabilities are being offered within the B2W Schedule application to assist contractors in managing trucking orders and assignments with online visibility and real-time agility.

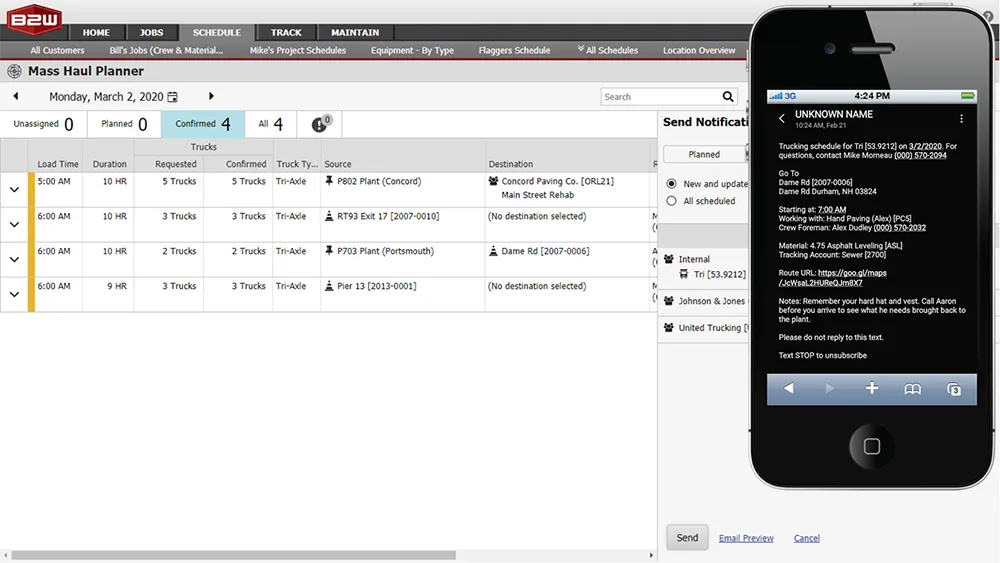

Schedulers and dispatchers can assign, view and modify truck requirements and deliveries being fulfilled by their own fleets and by outside, third-party contractors.

The firm says that the package provides a centralised view of resource needs and assignments, equipment moves, material orders and trucking requirements. Users access the system from desktop, laptop or mobile tablet devices and can customise one-day, multi-day or multi-week views according to their roles. Specific users can create and modify assignments based on permission levels.

Move Planner and Mass Haul Planner modules within B2W Schedule are used to manage equipment moves and mass haul schedules more efficiently. Notifications about these trucking assignments, including revisions to a schedule, can be communicated to drivers via text message or email.

B2W Schedule also assists in identifying and resolving scheduling conflicts and includes a Map View that uses GPS and telematics data to validate the location of resources.

The scheduling and dispatching application is part of B2W Software’s ONE Platform, which also includes capabilities for heavy construction field tracking and analysis and equipment maintenance as well as estimating, safety, e-forms and reporting.

Similarly, information on the status and availability of assets from the B2W Maintain application for equipment maintenance can be accessed in real time in B2W Schedule.