Rockmore International has given the European launch to the first model in its T series DTH (down the hole) hammer line, the ROK 600T. It is now being tested in Austria and Germany, and will be tested in a Belgian quarry in the next few months.

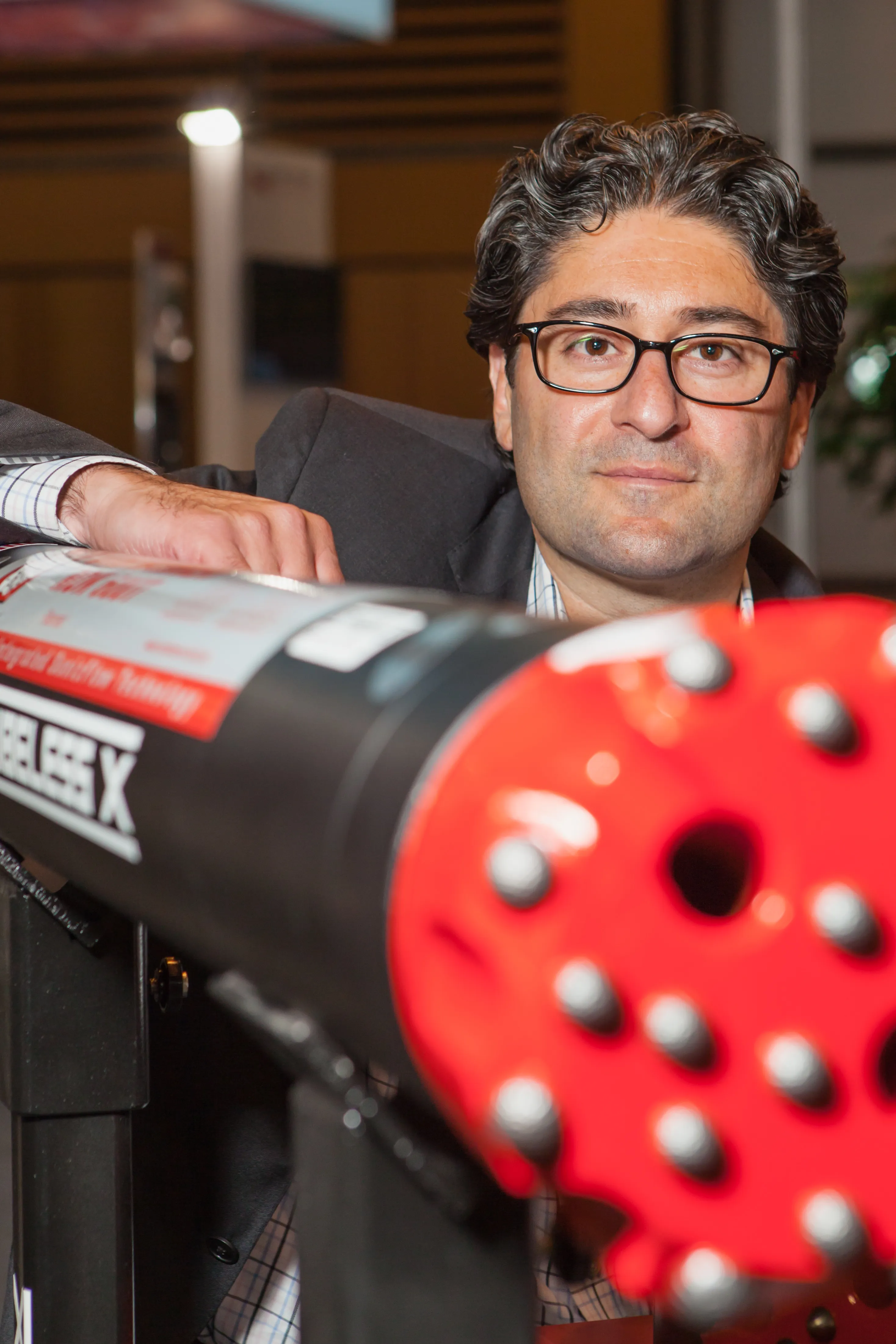

Pejman Eghdami, executive vice president, said the company is now actively promoting the hammer, which it describes as a breakthrough in DTH drilling technology for mining, construction and water well applications.

“We recognised a trending demand in the DTH drilli

January 6, 2017

Read time: 2 mins

Pejman Eghdami, executive vice president, said the company is now actively promoting the hammer, which it describes as a breakthrough in DTH drilling technology for mining, construction and water well applications.

“We recognised a trending demand in the DTH drilling sector for a high performance DTH tool that could utilise industry-standard drill bits without plastic components in order to increase reliability yet not compromise drilling efficiency,” he said.

The elimination of the plastic part associated with the drill bit is said to offer various technical and economic advantages in the T series, which is the result of extensive research, development and field-testing.

The ROK 600T is a six-inch class (152.4mm) model with high performance drilling characteristics rated for drilling 155-178mm diameter holes for blast hole applications in mining, quarrying and construction. It is also being promoted for water well drilling.