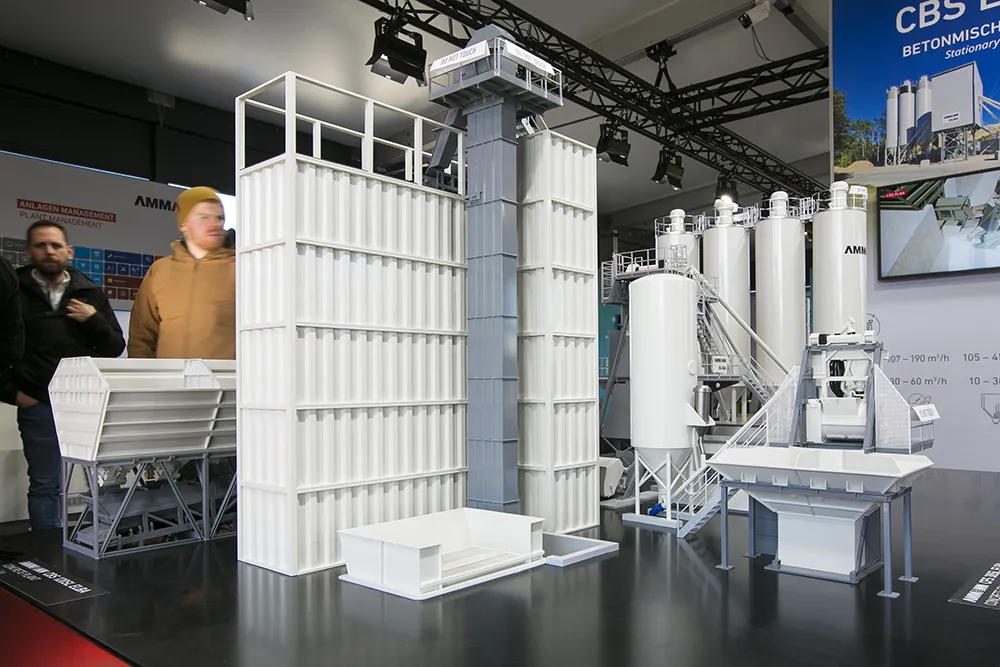

The new CBS Elba Concrete-Mixing Plant from the Ammann Group is a stationary unit that is said to offer high performance, versatility and sustainability. Engineered for medium- to high-capacity applications, it delivers exceptional results, producing up to 200m³ of compacted fresh concrete/hour. Its modular design ensures adaptability to diverse customer needs, making it the perfect choice for ready-mix and other demanding concrete applications.

With advanced aggregate storage options, such as high-raised enclosed chambers for superior environmental protection, it is said to set a new standard in eco-friendly and efficient concrete production. Engineered for long-term durability and tailored to adapt to evolving industry needs, the plant is a future-proof solution for modern concrete applications.