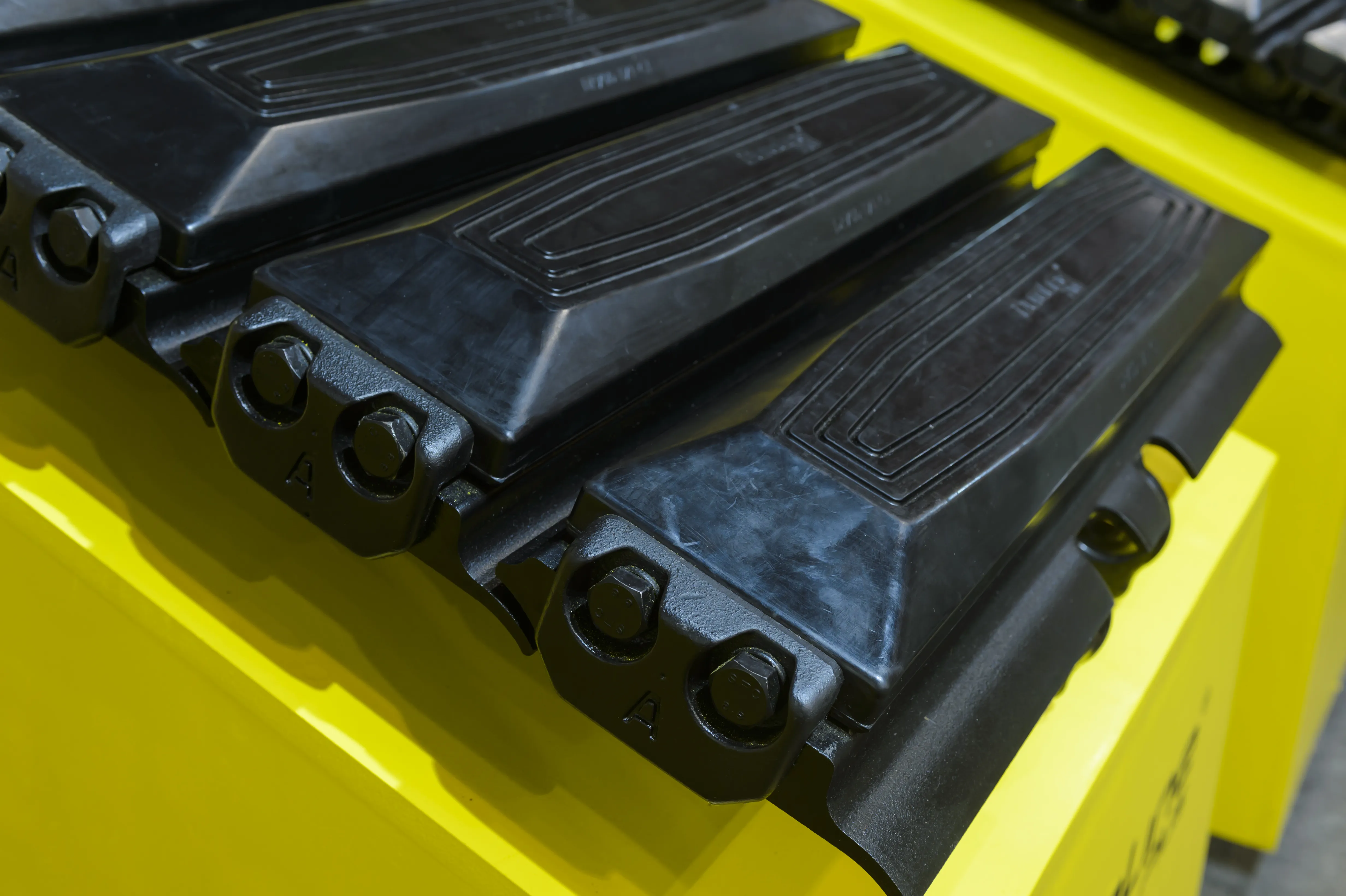

Spanish company MTG, which produces wear parts for the protection of buckets, has a new range of ProMet shrouds.

The ProMet system for construction machinery includes the new range of ProMet wing and blade shrouds, as well as more common weldable and bolt-on shrouds of the MTG Plus range.

They have all been specifically designed to ensure increased wear life and improved bucket performance in 30-85 tonne excavator and loader buckets.

MTG says that the system offers a wide range of reversible wing shrouds

January 6, 2017

Read time: 2 mins

Spanish company 7159 MTG, which produces wear parts for the protection of buckets, has a new range of ProMet shrouds.

The ProMet system for construction machinery includes the new range of ProMet wing and blade shrouds, as well as more common weldable and bolt-on shrouds of the MTG Plus range.

They have all been specifically designed to ensure increased wear life and improved bucket performance in 30-85 tonne excavator and loader buckets.

MTG says that the system offers a wide range of reversible wing shrouds that allow for changing the position to achieve the complete wear of the part and also avoids exposure by the bucket’ sides to impacts and abrasions, thus increasing its wear life.

The complete range is for wing widths of between 30-60mm, and it includes the MTGtwist hammerless system with the wear material index above 70%.

For mining machinery, MTG has a new range of wing and blade shrouds, which offer increased bucket protection and ensure improved performance for excavators (100-350tonnes) and loaders (95-250tonnes).

The ProMet system for construction machinery includes the new range of ProMet wing and blade shrouds, as well as more common weldable and bolt-on shrouds of the MTG Plus range.

They have all been specifically designed to ensure increased wear life and improved bucket performance in 30-85 tonne excavator and loader buckets.

MTG says that the system offers a wide range of reversible wing shrouds that allow for changing the position to achieve the complete wear of the part and also avoids exposure by the bucket’ sides to impacts and abrasions, thus increasing its wear life.

The complete range is for wing widths of between 30-60mm, and it includes the MTGtwist hammerless system with the wear material index above 70%.

For mining machinery, MTG has a new range of wing and blade shrouds, which offer increased bucket protection and ensure improved performance for excavators (100-350tonnes) and loaders (95-250tonnes).