Contractor Lyndon Thomas, in Northampton, England, has taken delivery of eight Doosan DA30-5 articulated dump trucks - the biggest single UK order for Doosan trucks.

The order also confirms Lyndon Thomas as the owner of the largest fleet of dump trucks in the East Midlands area. Established in 2010, Lyndon Thomas offers a range of services including earthmoving, contract crushing and screening, plant hire, demolition and distribution of all types of aggregate.

The Stage IV trucks were purchased along

January 12, 2017

Read time: 2 mins

Contractor Lyndon Thomas, in Northampton, England, has taken delivery of eight 695 Doosan DA30-5 articulated dump trucks - the biggest single UK order for Doosan trucks.

The order also confirms Lyndon Thomas as the owner of the largest fleet of dump trucks in the East Midlands area. Established in 2010, Lyndon Thomas offers a range of services including earthmoving, contract crushing and screening, plant hire, demolition and distribution of all types of aggregate.

The Stage IV trucks were purchased along with a Doosan 30tonne DX300LC-5 Stage IV crawler excavator from regional Doosan dealer Murley Construction.

Like all Doosan ADTs, the DA30-5 features an articulation hinge positioned behind the turning ring to provide equal weight distribution to the front axle even during maximum steer articulation. This together with a free-swinging rear tandem bogie ensures equal distribution of weight to each wheel and guarantees permanent six-wheel contact and drive for equal power distribution and excellent performance on difficult terrain.

Doosan said that the forward turning point, the tandem bogie and the sloping rear frame results in rough and soft terrain capabilities and avoids the need for electronic aids such as traction control.

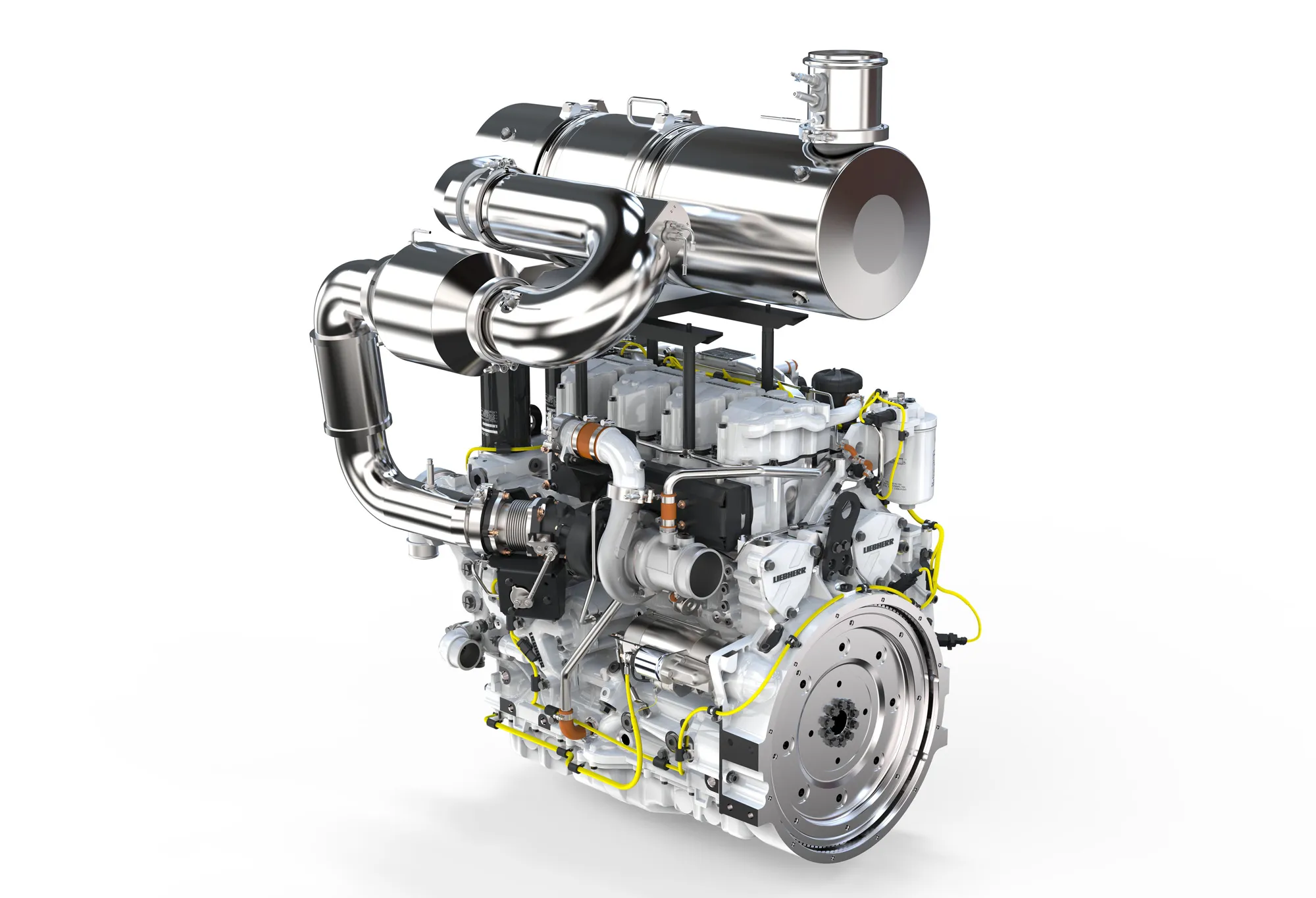

Lower fuel consumption of Doosan ADTs is down to a combination of features including a new759 Scania diesel engine and a ZF EP transmission that improves the transfer of power from the engine to the wheels. When this is coupled with the enhanced rear differential system it reduces engine rpm and further increases machine durability.

The Scania DC9 276kW diesel engine meets the Stage IV/Tier 4 Final emission regulations by way of Selective Catalytic Reduction (SCR) and Exhaust Gas Recirculation (EGR) technologies along with an electronic engine brake system, one of four brake systems on the trucks. Doosan’s Stage IV/Tier 4 Final ADTs do not need a diesel particle filter (DPF) to meet the emission regulations.

The new DX300LC-5 is also powered by the Scania DC9 five-cylinder diesel engine, with an output of 202kW of power at 1800 rpm, providing a 27% increase in engine power and a 30% boost in torque over the previous LC-3 model.

The order also confirms Lyndon Thomas as the owner of the largest fleet of dump trucks in the East Midlands area. Established in 2010, Lyndon Thomas offers a range of services including earthmoving, contract crushing and screening, plant hire, demolition and distribution of all types of aggregate.

The Stage IV trucks were purchased along with a Doosan 30tonne DX300LC-5 Stage IV crawler excavator from regional Doosan dealer Murley Construction.

Like all Doosan ADTs, the DA30-5 features an articulation hinge positioned behind the turning ring to provide equal weight distribution to the front axle even during maximum steer articulation. This together with a free-swinging rear tandem bogie ensures equal distribution of weight to each wheel and guarantees permanent six-wheel contact and drive for equal power distribution and excellent performance on difficult terrain.

Doosan said that the forward turning point, the tandem bogie and the sloping rear frame results in rough and soft terrain capabilities and avoids the need for electronic aids such as traction control.

Lower fuel consumption of Doosan ADTs is down to a combination of features including a new

The Scania DC9 276kW diesel engine meets the Stage IV/Tier 4 Final emission regulations by way of Selective Catalytic Reduction (SCR) and Exhaust Gas Recirculation (EGR) technologies along with an electronic engine brake system, one of four brake systems on the trucks. Doosan’s Stage IV/Tier 4 Final ADTs do not need a diesel particle filter (DPF) to meet the emission regulations.

The new DX300LC-5 is also powered by the Scania DC9 five-cylinder diesel engine, with an output of 202kW of power at 1800 rpm, providing a 27% increase in engine power and a 30% boost in torque over the previous LC-3 model.