JCB has developed what it says is the world’s first dual technology transmission designed specifically for its Loadall telescopic handlers, combining the best characteristics of powershift and hydrostatic drives.

The new Industrial DualTech VT variable transmission is at the heart of the 531-70 Industrial DualTech VT; 535-95 Industrial DualTech VT, and 541-70 Industrial DualTech VT Loadalls.

A version for the American market will be on show, but at its recent unveiling in the UK, JCB pointed to the ad

February 24, 2017

Read time: 2 mins

The new Industrial DualTech VT variable transmission is at the heart of the 531-70 Industrial DualTech VT; 535-95 Industrial DualTech VT, and 541-70 Industrial DualTech VT Loadalls.

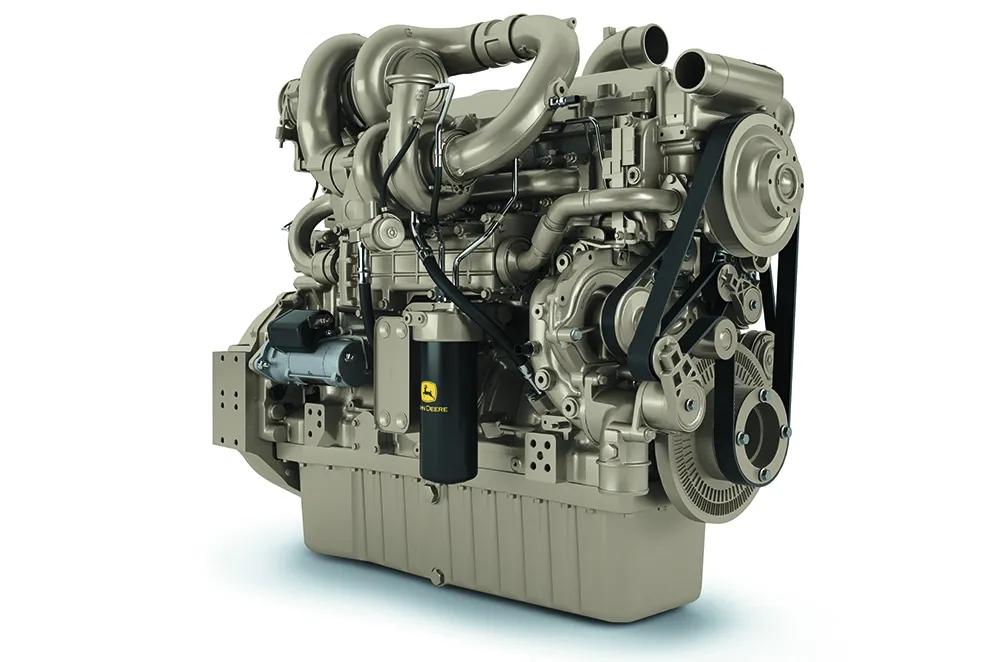

A version for the American market will be on show, but at its recent unveiling in the UK, JCB pointed to the advanced powertrain that brings together the power, torque and economy of the 4.8litre JCB EcoMAX engine with the new Industrial DualTech VT transmission.

“Industrial DualTech VT truly provides the best of both worlds, combining the low-speed controllability and easy driving characteristics of hydrostatics with the higher speed efficiency of direct drive powershift,” said Tim Burnhope, JCB chief engineering and innovation officer.

“Combining the superior high speed efficiency and towing ability of a JCB powershift transmission with the low-speed precision control advantages of a hydrostatic drive creates the ideal combination for operators who want maximum productivity and efficiency, and a premium driving experience.”

When the Industrial DualTech VT accelerates beyond 19km/hour, the Industrial DualTech VT variable transmission automatically switches to its powershift system, where electronically modulated clutch packs make barely noticeable shifts between three mechanical gears.