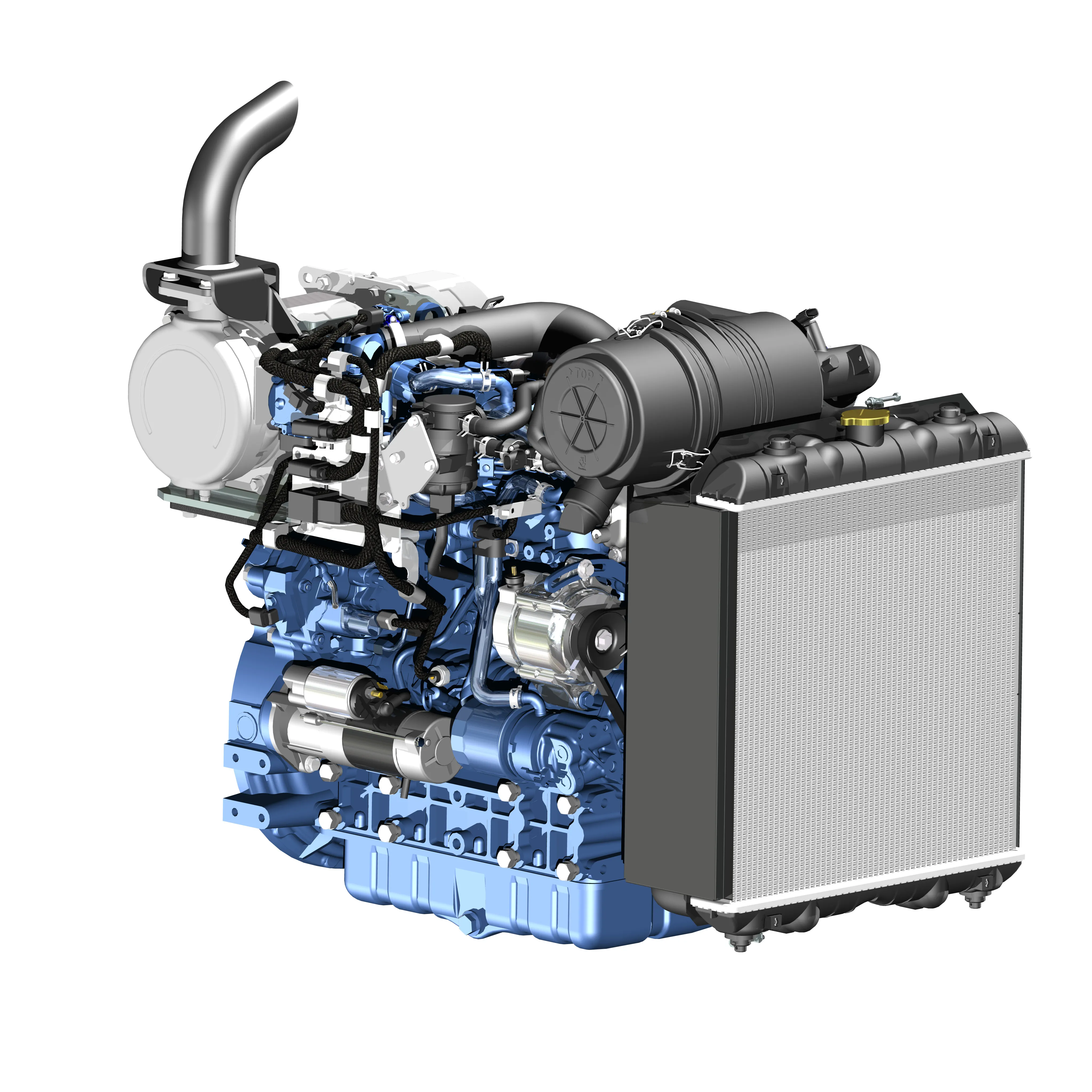

Perkins Engines is launching a range of additional engines to complete its offer to OEMs. The revised line-up will provide a global solution, with common mounting points and ancillary systems to meet a range of emissions standards around the world. The move will allow customers to buy a single engine family and specify a range of power outputs for sale in different territories, with reduced parts stock and improved commonality of components.

Perkins has also joined forces with an oil supplier to develop it

March 14, 2016

Read time: 1 min

Perkins has also joined forces with an oil supplier to develop its own diesel engine oils. Initially serving the Tier 3 and below markets, Perkins engine oils provide 500 hour service intervals and can be supplied through all Perkins distributors worldwide. Additional oils, for higher emission engines will be added as the range grows.