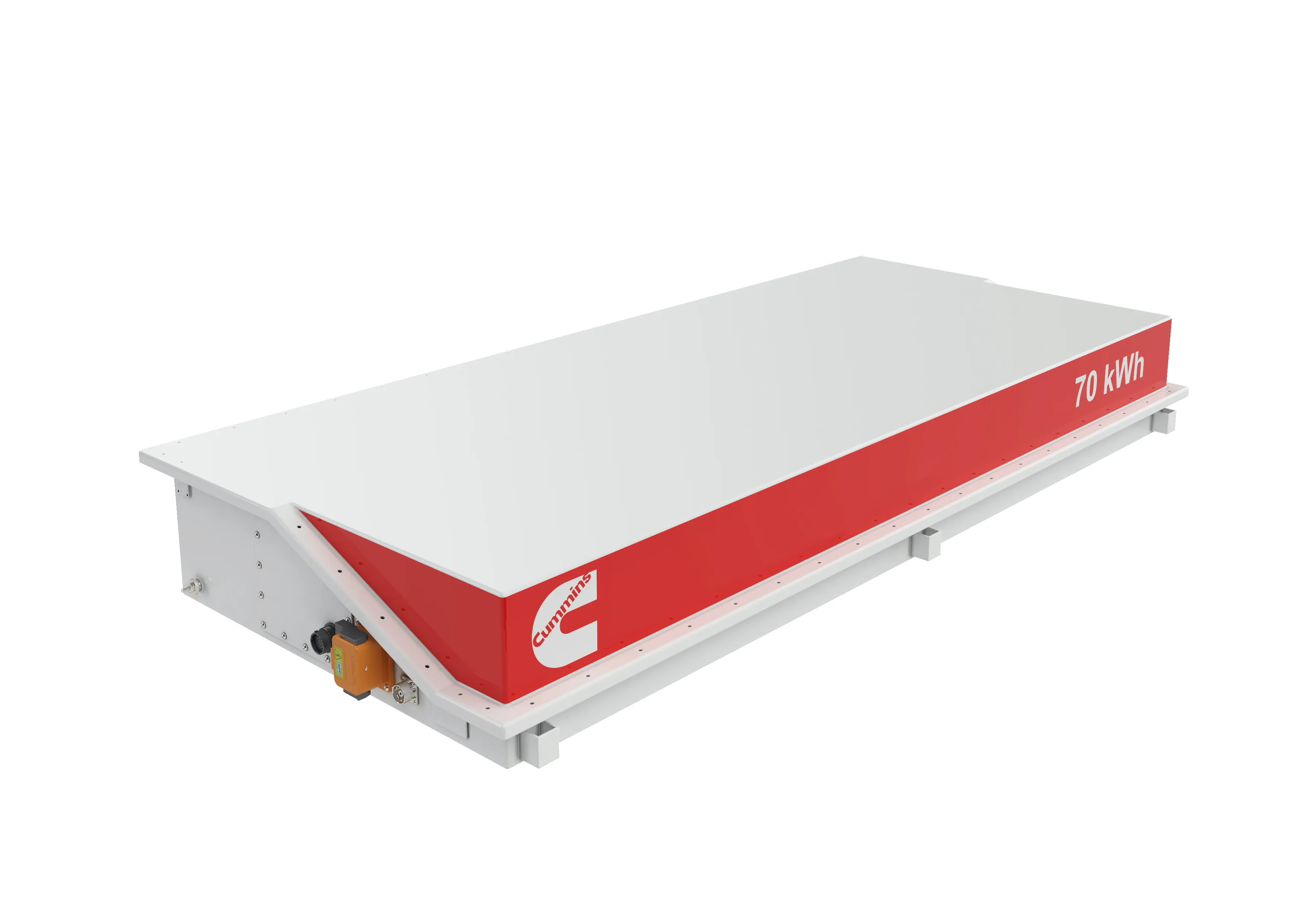

This power package is intended to take the place of diesels with capacities of up to 9litres, for use in a wide range of construction machine installations, including wheeled loaders, excavators and mobile cranes. The diesel is linked to the generator, powering the high output motor with its continuous torque output of up to 1,850Nm. The system offers a peak torque output of 3,400Nm, for short term delivery however. The engine and generator automatically charge the battery pack as required, while the system also has a plug-in option for overnight recharging.

As the system is modular it could be scaled up or down in size to suit different applications. The firm says that the high-density battery pack and engine can also be sized to suit the installation space available. A spokesperson for the firm explained, “It gives the best solution for a wide range of drivelines. It’s flexible for different duty cycles as you can vary the battery size. It will go into production first for the bus market.”