Controls Group, an Italian testing equipment business specifically for the construction industry, is highlighting two products specifically for the highways sector – a bitumen analyser and a gyratory compactor.

In March last year, Controls bought the Australian business IPC Global and will showcase its new subsidiary’s Servopac 76-PV20A02, a fully automatic, servo-controlled gyratory compactor designed for asphalt mixes.

Users can set the needed axial stress, exceeding the requirements of AASHTO (American

February 10, 2015

Read time: 2 mins

In March last year, Controls bought the Australian business

Users can set the needed axial stress, exceeding the requirements of AASHTO (

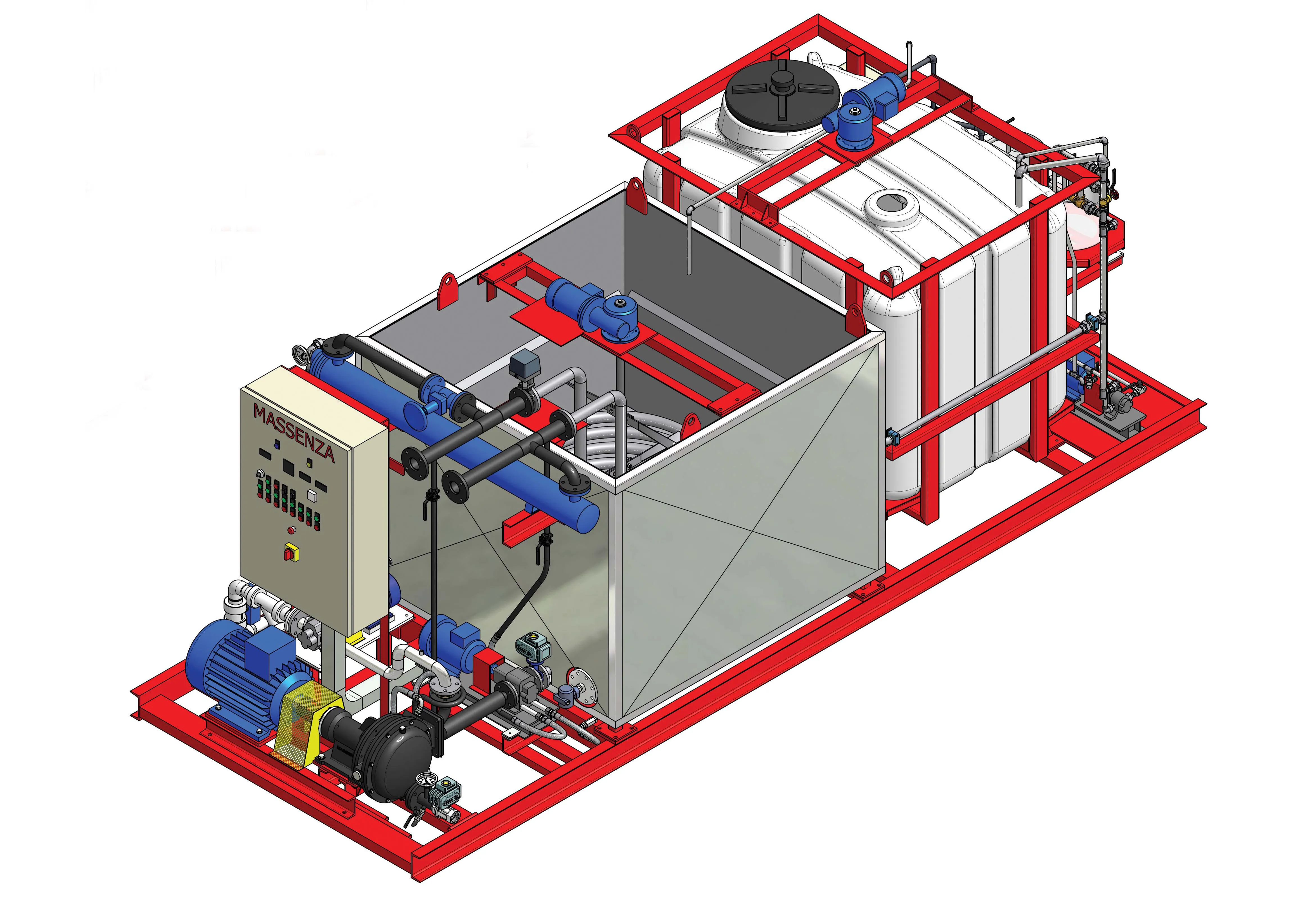

Highlighted also will be products from PaveLab Systems, another Controls Group subsidiary. The PaveAnalyser exractor 75-PV50A15 uses solvents to separate and extract bitumen, filler and aggregates from asphalt. It can determine the binder content or to recover, using a rotary extractor, a representative bitumen sample that can be used for other bitumen tests including penetration and softening points.