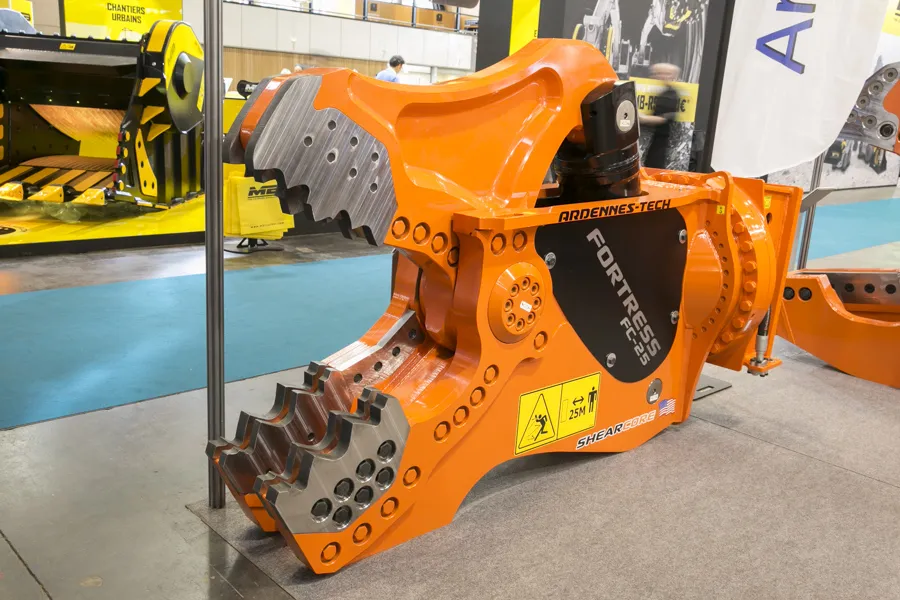

ShearCore's FC series of 'concrete cracker' shears features a narrow stick body for improved visibility for the operator and a removable isolated bottom cover for easy access to all serviceable components. The Fortress FC25 has a shear weight 2,722 kg, jaw opening of 813 mm and jaw depth of 722 mm, with a reach of 2,565 mm. Minimum excavator boom mount is 14 tonnes, and stick mount is 20 tonnes.

The Model FS45R shear weighs 5,307 kg, with jaw opening and jaw depth both 711mm. Reach is 3327 mm. Minimum excavator boom mount is 25 tonnes and maximum excavator stick mount is 41 tonnes. The shears have large access panels that are removable for component replacement. The upper and lower jaws are made from 152.4mm (6 inches) high-yield structural plate steel, eliminating the need for laminations. A large pivot group avoids the need for auto guide and improves performance and durability, which is also improved through nitrocarburised swivel components.

Ardennes Tech distributes the shears in France, Belgium, Luxembourg and the Dom-Tom French overseas territories. It was time for the French market to have a new brand of shears available, says the company's chief executive Joël Barbotin.