Latest Volvo wheeled loaders to get the G-series revisions include the middle-weight 11-17 tonne L60, L70 and L90 versions. The stylish overhaul brings an electrically operated sloping bonnet, improving rearward visibility. All benefit from a revised cab layout, cleaner engines and improved hydraulic systems to deliver more productivity and greater efficiency. Power ratings are from 121-130kW, with all three sharing a stage IIIB six-cylinder Volvo D6H motor that gets cooled EGR and DPF emissions equipment.

January 6, 2017

Read time: 2 mins

Latest 2394 Volvo wheeled loaders to get the G-series revisions include the middle-weight 11-17 tonne L60, L70 and L90 versions.

The stylish overhaul brings an electrically operated sloping bonnet, improving rearward visibility. All benefit from a revised cab layout, cleaner engines and improved hydraulic systems to deliver more productivity and greater efficiency.

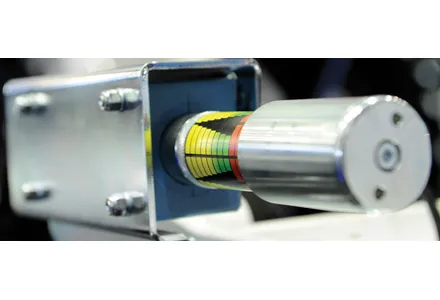

Power ratings are from 121-130kW, with all three sharing a stage IIIB six-cylinder Volvo D6H motor that gets cooled EGR and DPF emissions equipment.

The D6H engine means the L70G and L90G give full power from 1,400-1,700rpm, with the L60G extending to 1,800rpm.

Volvo says that matching the engine, drivetrain and load-sensing hydraulic system has brought greater efficiency and faster cycle times. All three retain Volvo’s torque-parallel linkage, with the L90G for example, getting a 23per cent increase in lifting force and 19per cent more breakout.

Maximum static tipping loads at full turn are 7,440kg, 8,460kg and 9,530kg respectively.

Fully automated powershift transmissions offer a choice of four gear-shifting programmes and an ‘eco’ accelerator pedal. The latter it delivers a greater amount of pedal back-pressure to encourage lower fuel consumption from those with a heavy right foot.

2 Internal 2 4824 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/intermat-2012/video/ true false %>

The stylish overhaul brings an electrically operated sloping bonnet, improving rearward visibility. All benefit from a revised cab layout, cleaner engines and improved hydraulic systems to deliver more productivity and greater efficiency.

Power ratings are from 121-130kW, with all three sharing a stage IIIB six-cylinder Volvo D6H motor that gets cooled EGR and DPF emissions equipment.

The D6H engine means the L70G and L90G give full power from 1,400-1,700rpm, with the L60G extending to 1,800rpm.

Volvo says that matching the engine, drivetrain and load-sensing hydraulic system has brought greater efficiency and faster cycle times. All three retain Volvo’s torque-parallel linkage, with the L90G for example, getting a 23per cent increase in lifting force and 19per cent more breakout.

Maximum static tipping loads at full turn are 7,440kg, 8,460kg and 9,530kg respectively.

Fully automated powershift transmissions offer a choice of four gear-shifting programmes and an ‘eco’ accelerator pedal. The latter it delivers a greater amount of pedal back-pressure to encourage lower fuel consumption from those with a heavy right foot.

%$Linker: