Bobcat has launched a sonic tracer system for use with its two largest 244cm and 274cm heavy duty grader attachments.

January 6, 2017

Read time: 1 min

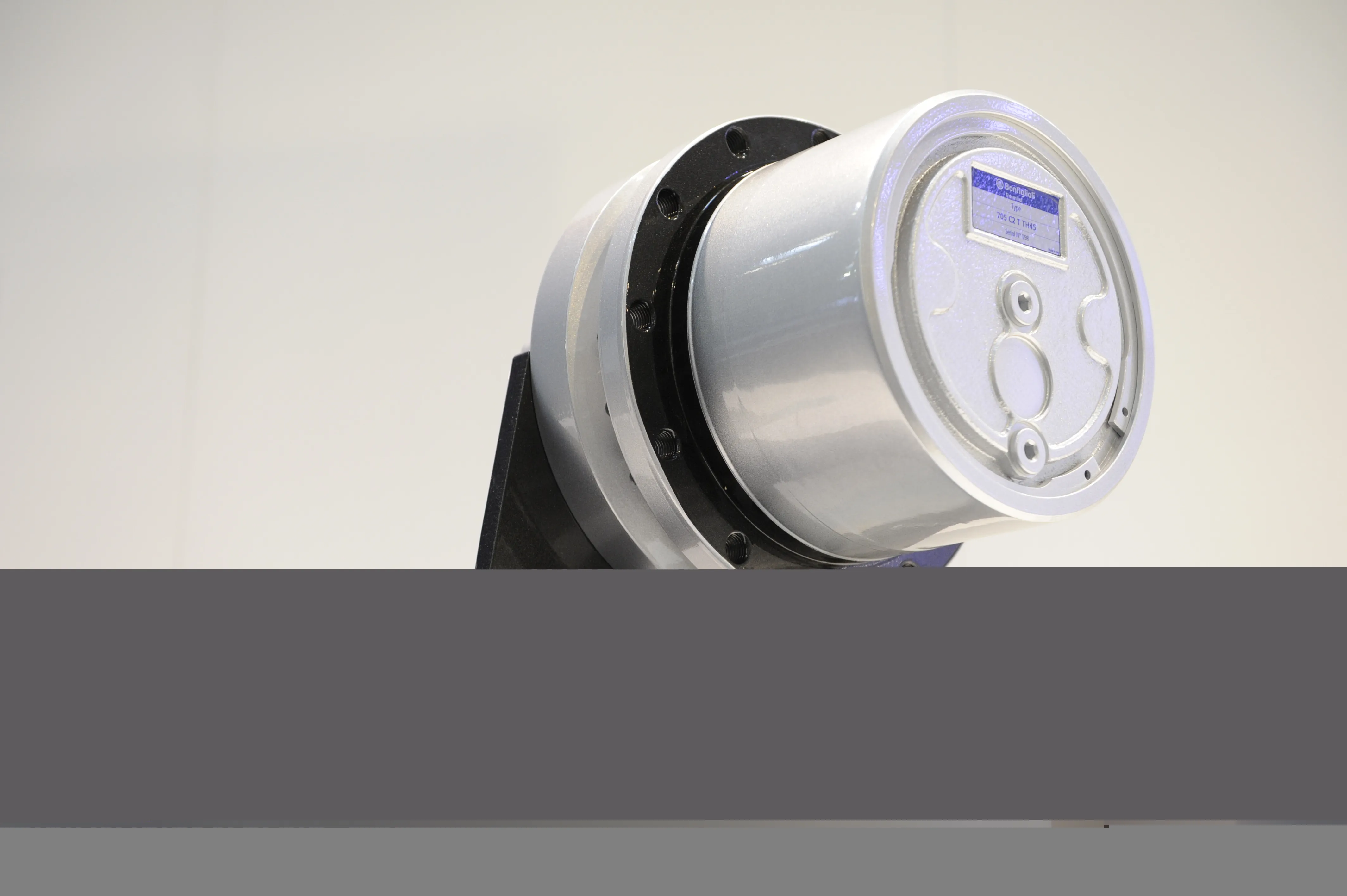

The system uses

The tracer emits ultra sonic signals to maintain a set distance or elevation from an object, surface or the ground. Installed on the grader’s blade, the tracer allows these attachments to grade, level, and backfill on a multiple slope terrain when following a string line, kerbstone, the gutter or even a previous pass as a grade control.

Grade accuracy, said Bobcat, is 6.4mm, and the detection range of the sonic tracer is from 200-1,300mm.

Large grader attachments and the sonic tracer system is compatible with the Bobcat A770 all-wheel-steer loader, S770 and S850 skid-steers, and T650, T770 and T870 compact tracked loaders.

%$Linker:

Hall: 6 Stand: G079

%$Linker: