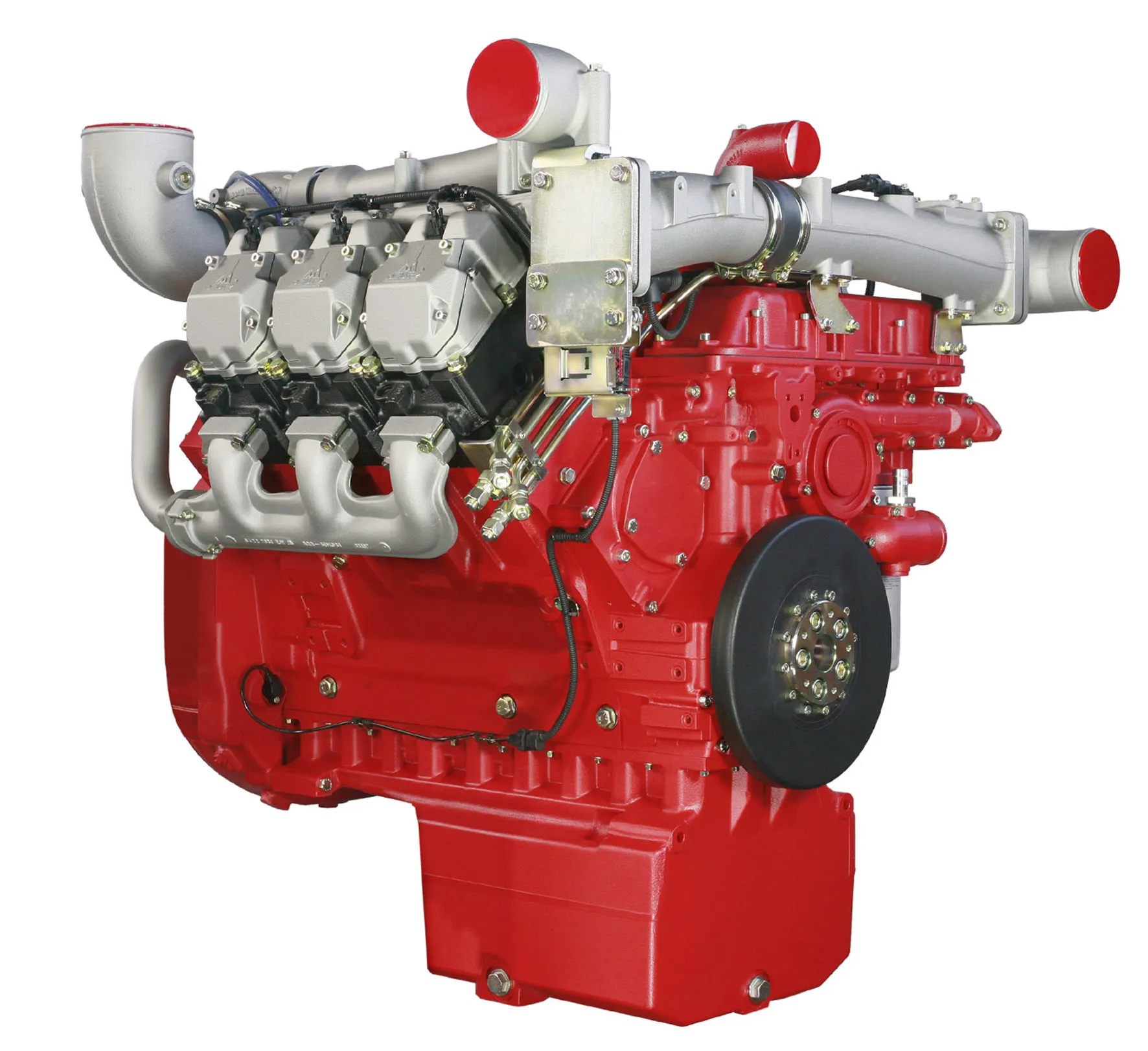

The new Tier 4 Final/Stage IV emission certified engine range from Deutz is being introduced. This complete line-up of diesels meets the coming noise and exhaust emission requirements in Europe and the US and offers capacities from 2.9-16litres. The low emissions performance is achieved using the Deutz DVERT technology, a package of technical solutions that is used in modular form with varying options used to ensure each engine capacity meets the requirements. Compact design and high torque output are claim

January 6, 2017

Read time: 2 mins

The new Tier 4 Final/Stage IV emission certified engine range from 201 Deutz is being introduced. This complete line-up of diesels meets the coming noise and exhaust emission requirements in Europe and the US and offers capacities from 2.9-16litres. The low emissions performance is achieved using the Deutz DVERT technology, a package of technical solutions that is used in modular form with varying options used to ensure each engine capacity meets the requirements. Compact design and high torque output are claimed across the range and Deutz says that the engines offer higher power density than previous generation units, allowing these diesels to take the place of larger capacity motors available earlier. This design allows space in an engine compartment for hydraulics as well as the exhaust filtration and after-treatment systems. The range starts with the compact 2.9litre TCD2.9L4 engine, a four cylinder unit available in both turbocharged and naturally aspirated versions and which offers power outputs from 30-55kW while being designed to fit into tight installations. The TCD3.6L4 and TCD4.1L4 are also four cylinder units with power outputs from 56-97kW and 80-115kW respectively, while the TCD6.1L6 and TCD7.8L6 are six cylinder engines available in ratings from 100-180kW and 160-250kW respectively. The TCD12.0V6 has power ratings from 240-390kW and has a V6 configuration, while its larger size means it features emission systems from the DVERT range including selective catalytic reduction (SCR), as well as cooled external exhaust gas regeneration (EGR) and a particulate filter. The V8 configuration, 16litre engine is due shortly and will offer power ratings up to 520kW, as well as using similar emissions systems to the V6 diesel. All the engines are said to benefit from low fuel consumption, helping to reduce running costs for the owner and offsetting the additional cost of the emissions package.2 Internal <?xml version="1.0" encoding="utf-16"?><dictionary /> 2 11560 0 oLinkInternal <span class="oLinkInternal"><span class="oLinkInternal">View more videos</span></span> Video false /event-news/bauma-2013/video/ true false %>

Stand: A4.321/416

%$Linker: