TanGO, a new tangential oscillation system, has been launched at bauma 2013 by BOMAG. The company has reassessed many details of the well-established exciter system in terms of both technical and cost-effective aspects, and optimised it in key areas. BOMAG oscillation makes use of the physical laws of vibration generation to best effect. The careful coordination of exciter system to drum weight ratios is the basis for the tangential oscillation. The result is clearly improved power for vibration generation

January 6, 2017

Read time: 2 mins

TanGO, a new tangential oscillation system, has been launched at bauma 2013 by 172 Bomag.

The company has reassessed many details of the well-established exciter system in terms of both technical and cost-effective aspects, and optimised it in key areas.

BOMAG oscillation makes use of the physical laws of vibration generation to best effect. The careful coordination of exciter system to drum weight ratios is the basis for the tangential oscillation. The result is clearly improved power for vibration generation and perfectly matched compaction parameters.

The exciter system, with tangential oscillation, is particularly suitable for use on bridge structures and close to buildings, where it hardly produces vibrations, and yet compacts efficiently. Tangential oscillation is always directed horizontally, maintaining continuous ground contact due to the constant transfer of gravity.

Users are often able to see the increased efficiency in compaction due to tangential oscillation immediately after a few roller passes. Furthermore, the interplay of tangential oscillation and vibration in the front drum results in the exciter systems interacting in a highly beneficial way.

Exciter systems by BOMAG have a big practical advantage, with mixes that are difficult to compact by vibration alone, or which have high shearing strength.

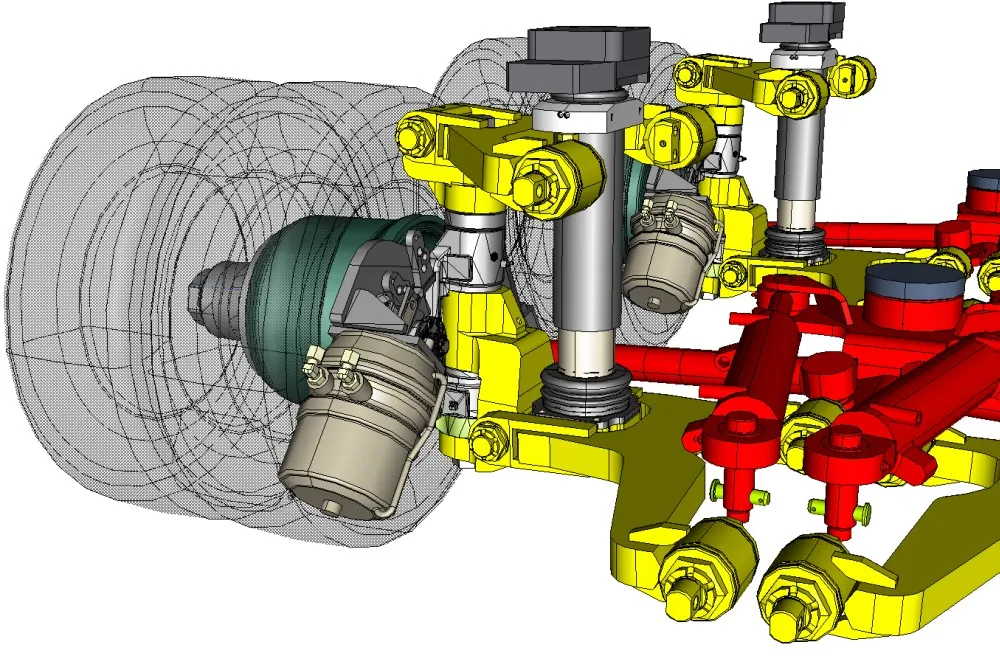

The new BOMAG TanGO system is located in the rear drum of tandem rollers; it can be combined with a vibrating drum at the front depending on the application. The system has a modular structure, which means all heavy tandem rollers can be equipped with it depending on drum width and diameter.

BOMAG will begin offering rollers with tangential oscillation in the 10tonne class with the roller type BW 161 ADO-4. However, it is also planning introductions into other weight classes.

The company has reassessed many details of the well-established exciter system in terms of both technical and cost-effective aspects, and optimised it in key areas.

BOMAG oscillation makes use of the physical laws of vibration generation to best effect. The careful coordination of exciter system to drum weight ratios is the basis for the tangential oscillation. The result is clearly improved power for vibration generation and perfectly matched compaction parameters.

The exciter system, with tangential oscillation, is particularly suitable for use on bridge structures and close to buildings, where it hardly produces vibrations, and yet compacts efficiently. Tangential oscillation is always directed horizontally, maintaining continuous ground contact due to the constant transfer of gravity.

Users are often able to see the increased efficiency in compaction due to tangential oscillation immediately after a few roller passes. Furthermore, the interplay of tangential oscillation and vibration in the front drum results in the exciter systems interacting in a highly beneficial way.

Exciter systems by BOMAG have a big practical advantage, with mixes that are difficult to compact by vibration alone, or which have high shearing strength.

The new BOMAG TanGO system is located in the rear drum of tandem rollers; it can be combined with a vibrating drum at the front depending on the application. The system has a modular structure, which means all heavy tandem rollers can be equipped with it depending on drum width and diameter.

BOMAG will begin offering rollers with tangential oscillation in the 10tonne class with the roller type BW 161 ADO-4. However, it is also planning introductions into other weight classes.

Stand: F10.1009

%$Linker: