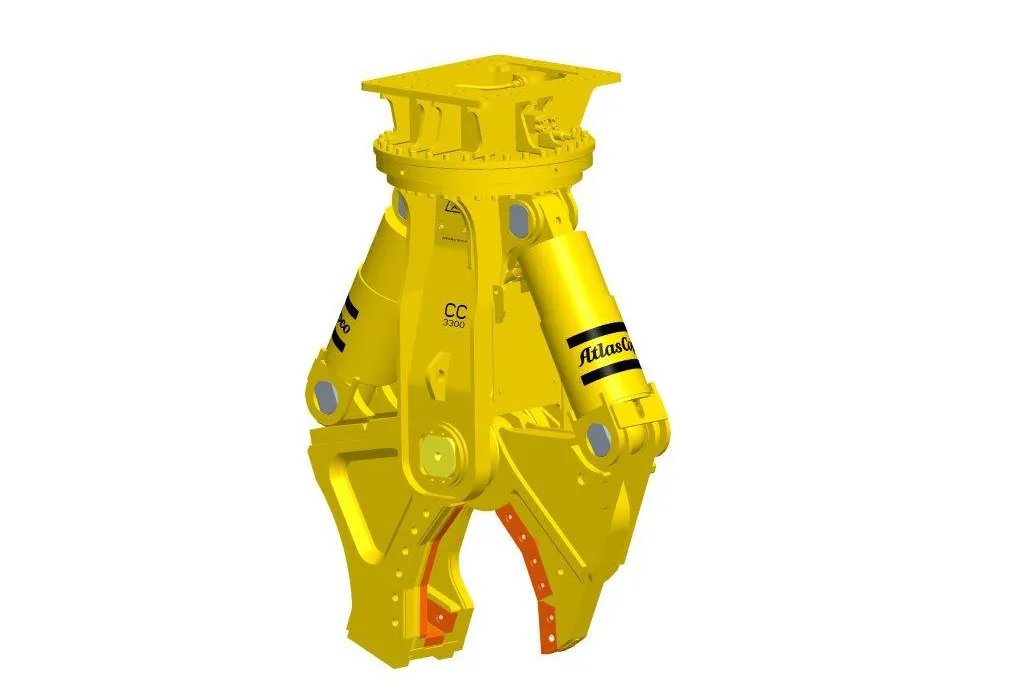

Atlas Copco is launching a new jaw variant that turns its CC 3300 Combi Cutter into a mobile shear. “Our aim is to be a leading manufacturer and solution provider for the demolition market. To round off our offerings in the silent demolition tools segment, we are introducing a mobile shear jaw for our CC 3300 Combi Cutter,” explains Wolfgang Hohn, product line manager, silent demolition tools.

January 6, 2017

Read time: 2 mins

“Our aim is to be a leading manufacturer and solution provider for the demolition market. To round off our offerings in the silent demolition tools segment, we are introducing a mobile shear jaw for our CC 3300 Combi Cutter,” explains Wolfgang Hohn, product line manager, silent demolition tools.

With the new mobile shear (MS) jaw, Atlas Copco says it addresses the global demolition and recycling industry as well as scrap yards.

The CC 3300 follows the design of the entire product line of Atlas Copco hydraulic Combi Cutters. The system with the two movable jaws and the two lifting cylinders is said to offer a constantly high crushing force throughout the entire closing process. And the combination of a single and double-blade jaw arm provides maximum stability even under extreme loads.

The new MS version is an addition to the universal jaws (U version), steel cutting jaws (S version for secondary reduction) and box-shape jaws (B version) which are all available for the CC 3300.

A central main pin supports the cutter jaws in a stable manner, a concept that also reduces the time needed to change the cutter jaws by up to 75% compared to separately supported jaws, sasy Atlas Copco.

%$Linker: