The ALLU Screener Crusher D-series is divided into two main categories: screening and crushing and fine screening, and it is presenting a “new screening concept for bucket-type fine screening.” The company says that with the totally new screening design, wet materials can also be screened down to a fine fragment size such as 15 or 25mm minus, with high productivity. With the new design vaulting or bridging between the screening discs can be minimised.

February 5, 2013

Read time: 1 min

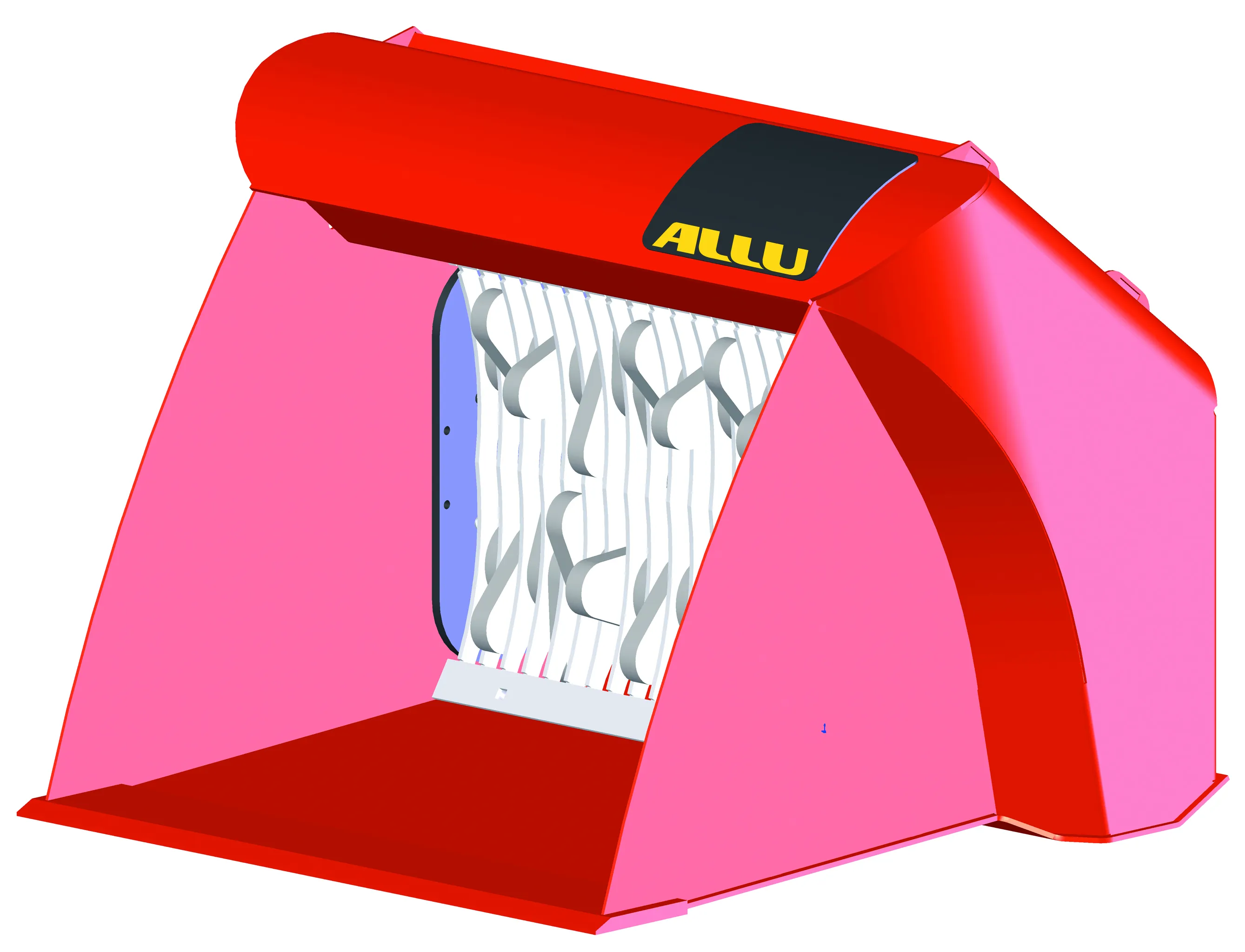

The 2180 ALLU Screener Crusher D-series is divided into two main categories: screening and crushing and fine screening, and it is presenting a “new screening concept for bucket-type fine screening.”

The company says that with the totally new screening design, wet materials can also be screened down to a fine fragment size such as 15 or 25mm minus, with high productivity. With the new design vaulting or bridging between the screening discs can be minimised.

ALLU is also widening its product range to cover smaller base machines too by introducing three new fine screening bucket models for excavators under 12tonnes and wheeled loaders maximum 5tonnes.

“The complete ALLU D –series product programme now includes models for 5-45tonne excavators and 2-30tonne wheeled loaders. ALLU buckets can be installed also on backhoes, skid steers and telescopic loaders,” says the company.

The company says that with the totally new screening design, wet materials can also be screened down to a fine fragment size such as 15 or 25mm minus, with high productivity. With the new design vaulting or bridging between the screening discs can be minimised.

ALLU is also widening its product range to cover smaller base machines too by introducing three new fine screening bucket models for excavators under 12tonnes and wheeled loaders maximum 5tonnes.

“The complete ALLU D –series product programme now includes models for 5-45tonne excavators and 2-30tonne wheeled loaders. ALLU buckets can be installed also on backhoes, skid steers and telescopic loaders,” says the company.

%$Linker: